What is an SF6 Gas Circuit Breaker?

Circuit breakers are essential for protecting electrical power stations and distribution systems as they interrupt the flow of electricity when an issue is detected. When a fault occurs, such as a power surge, insulation failure, or short circuit, circuit breakers trip to prevent damage to transformers, transmission lines, and other critical components.

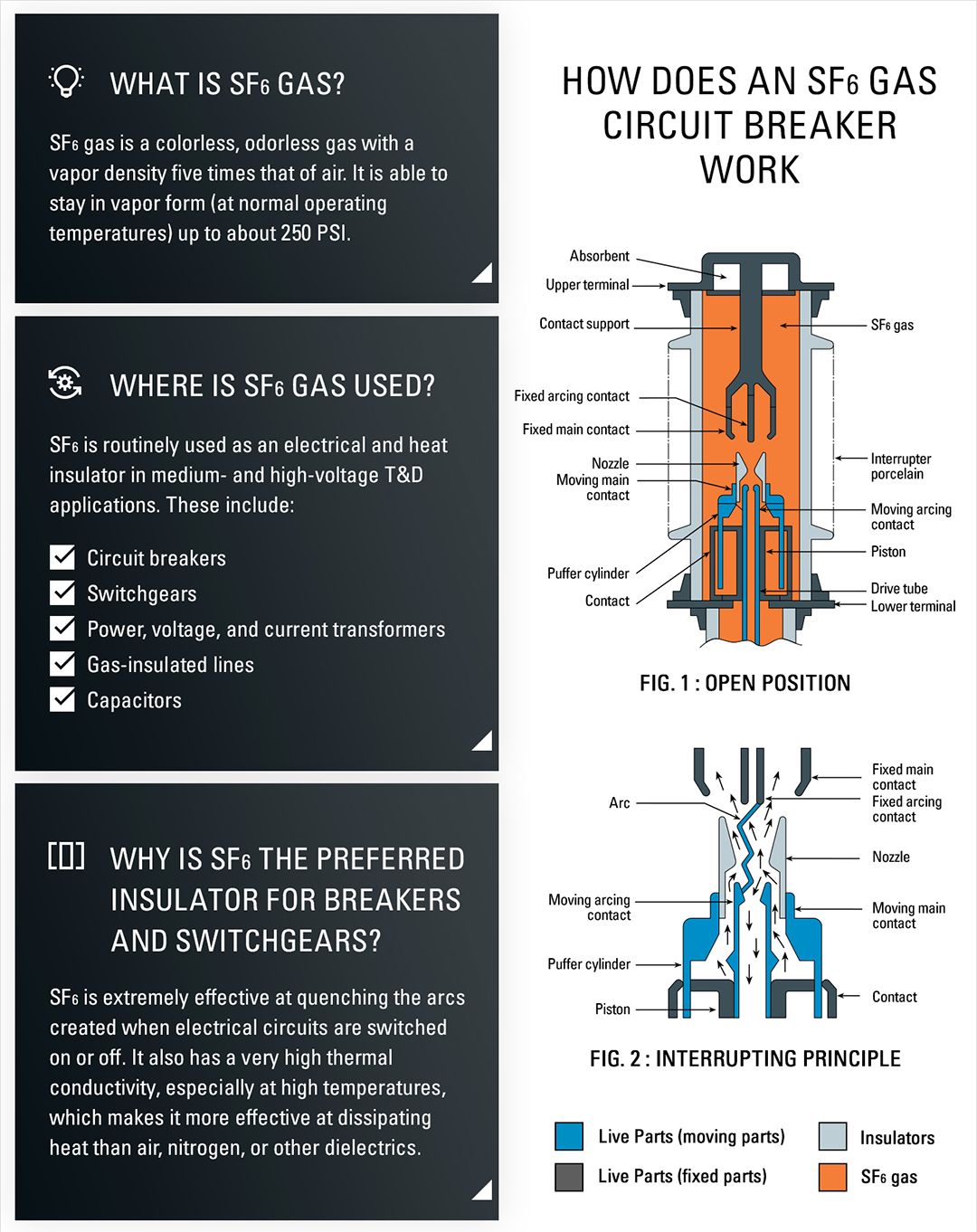

SF6 gas is inert, non-flammable, non-toxic, thermally stable, and has unmatched arc-quenching capabilities. It is more effective at dissipating heat than air, nitrogen, or other dielectrics. SF6 requires a lot of heat to break down the bonds between the molecules. When the heat source is removed the atoms begin to recombine immediately. The chemical properties of SF6 make it ideal for use within circuit breakers and switchgear. SF6 gas has excellent thermal transfer characteristics, so it works to absorb the energy of the arc. This creates resistance across the arcing contacts and eventually extinguishes the arc. Once the arc is extinguished, the SF6 gas begins to regenerate almost immediately.

SF6 circuit breakers use sulfur hexafluoride (SF6) gas as their insulating and arc-quenching medium. Unlike circuit breakers that rely on air, oil, or vacuum to extinguish electrical arcs, SF6 breakers offer superior dielectric strength and thermal stability. This makes them highly effective in medium- and high-voltage applications, ensuring reliable power distribution and transmission.

Uses of SF6 Circuit Breakers

Power Distribution Networks

SF6 circuit breakers are a key component in medium- and high-voltage electrical power distribution networks. Their primary function is to interrupt the flow of electricity when faults occur, preventing damage to transformers, underground cables, and electrical substations.

Since power distribution networks operate at varying voltage levels, the ability of SF6 circuit breakers to perform effectively under different conditions makes them essential in maintaining stable electricity supply across cities, industries, and remote areas.

Switchgear Systems

Switchgear systems are crucial for controlling and protecting electrical networks. These systems house various components, including circuit breakers, to ensure seamless power management.

SF6 circuit breakers are an integral part of switchgear in substations and electrical grids, as they provide reliable current interruption under both normal operating conditions and during electrical faults.

Their superior insulating properties and rapid arc-extinguishing capabilities help maintain grid stability and prevent extended power outages.

Transformer Protection

Transformers regulate voltage levels in power systems, ensuring that electricity is transmitted efficiently from power plants to homes and businesses. However, they are vulnerable to faults such as overvoltage conditions, internal insulation breakdowns, and external disturbances.

SF6 circuit breakers help protect transformers by isolating faulty units from the grid, minimizing the risk of damage and preventing disruptions to the power supply. This protective mechanism is essential in maintaining the longevity and efficiency of transformers in power distribution networks.

High Voltage Transmission Lines

High-voltage transmission lines are responsible for carrying electricity over long distances, often from power plants to regional substations. These lines are exposed to external threats such as lightning strikes, environmental contamination, and equipment failures.

SF6 circuit breakers provide an essential layer of protection by quickly detecting and interrupting electrical faults before they escalate. By doing so, they prevent equipment damage, enhance grid resilience, and ensure that high-voltage transmission systems remain operational.

Why SF6 Gas is Ideal for Circuit Breakers

SF6 gas is widely regarded as the most effective insulating and arc-quenching medium available for circuit breakers.

Here’s why:

Superior Insulation Properties: SF6 has a much higher dielectric strength than air or oil, allowing it to withstand high voltage levels without breaking down. This makes it ideal for use in compact circuit breakers designed for high-voltage applications.

Efficient Arc Quenching: When an electrical arc forms due to a fault, SF6 gas absorbs the arc energy and rapidly cools it down. This interrupts the current flow and prevents further damage to the electrical system.

Thermal Stability: SF6 gas remains stable even under extreme temperatures and pressure variations, ensuring consistent performance in different environmental conditions.

Self-Healing Capability: After extinguishing an arc, SF6 gas quickly recombines back into its original molecular form, making it highly reusable and effective for prolonged operation.

Non-Flammable and Non-Toxic: Unlike oil-based breakers, SF6 circuit breakers eliminate the risk of fire hazards and contamination, making them safer for use in high-voltage applications.

Advantages of SF6 Circuit Breakers

The introduction of SF6 circuit breakers has transformed the electrical industry by addressing the limitations of older breaker technologies. Here are some key advantages:

Lower Maintenance Requirements

Unlike oil circuit breakers, which require frequent maintenance to replace contaminated oil, SF6 breakers require minimal upkeep due to the gas’s self-regenerating properties.

Compact Design

The high dielectric strength of SF6 allows for more compact breaker designs, making them ideal for applications where space is limited, such as urban substations and industrial plants.

Longer Operational Lifespan

SF6 circuit breakers have a significantly longer service life compared to air or oil-based breakers, reducing the need for frequent replacements.

Reliable Performance in Harsh Conditions

SF6 breakers are designed to operate efficiently in extreme weather conditions, including high altitudes and humid environments, making them suitable for a wide range of geographic locations.

SF6 Gas Circuit Breaker Testing

Circuit breakers are designed to clear faults to protect electrical power stations; however, in normal conditions, these breakers are only in operation for a matter of minutes of their entire 20-plus-year lifespan.

Over time, moving parts on circuit breakers wear, alignments and clearances change, and critical functions can be negatively affected. How can you ensure that an SF6 gas circuit breaker will work when you need it to?

That’s where “Doble testing”, or power factor testing, comes into play. The Doble test detects the presence of contamination or deterioration of the breaker insulating system.

The Doble test can detect issues including:

· Moisture contamination

· Corrosion of insulating components

· Damage of components like operating rods and interrupters

Circuit breaker testing reveals these and other changes, in advance of a failure. If any problems are found, corrective action can be taken to safeguard the reliability of the breaker.

Gas Handling Recommendations for SF6 Circuit Breakers

During routine maintenance of an SF6 gas circuit breaker or in the event of a failure, the gas insulated equipment may need to be opened. This requires SF6 gas handling to remove as much gas as possible and place the breaker into the vacuum to avoid SF6 emissions. In its pure form, SF6 gas is inert and non-toxic; however, dangerous SF6 by-products form when the gas is exposed to a fault. By-products such as SO2 can also form when SF6 circuit breakers are in service for a long time and exposed to high heat and moisture.

We always recommend checking the quality of SF6 gas with an analyzer before beginning any handling procedures as by-products of SF6 are extremely hazardous to human health. In addition, by-products will damage gas handling equipment and accessories. Special PPE must be worn, and best-practices must be followed to ensure the safety of technicians. You can learn more by enrolling in the Emergent By-Product Cleanup Services offered in DILO Academy.

In addition to being aware of the gas quality and knowing how to handle SF6 by-products correctly, users must also take great care to avoid producing any SF6 emissions. SF6 gas has the highest Global Warming Potential of any gas known to man. Ideally, SF6 should be handled in a closed-loop system. Proper training and emission-free SF6 gas handling equipment is very important to prevent emissions.

SF6 Safety & Handling and Circuit Breaker Testing Fundamentals Training

This IACET-accredited course focuses on theoretical aspects and in-depth hands-on training. Check out the SF6 Safety & Handling and Circuit Breaker Testing Fundamentals Training in DILO Academy.

The first two days focus on SF6 gas theory and practical equipment demonstrations to provide technicians with vital knowledge for optimizing SF6 gas handling practices, safety procedures, and regulations/reporting.

In partnership with Doble, the second two days will cover circuit breaker testing. An introduction of various mechanism types, interrupters and testing methodologies will be discussed. For each test, there will be an in-depth discussion of each measurement, setup and test methodology, and acceptance criteria. A Vanguard specialist will provide training to decipher and review apparatus test results so that they are clear and easy to understand. Test results will be used for reporting and maintenance purposes and used for historical data samples to improve maintenance schedules.

Learning Objectives

Upon completion of this course, the participant will be able to:

· Describe characteristics of SF6, including history, properties, and contaminants

· Compare and contrast virgin and reconditioned SF6 gas

· Use an emission-free approach for SF6 gas analysis

· Employ best safety practices for hands-on SF6 gas handling and safety methods

· Create and apply a zero-emissions approach to SF6 gas handling, including recovery, filling, and evacuation

· Identify current environmental standards at a local and federal level

· Discuss important DOT/transportation and certification requirements and considerations for SF6 gas cylinders

· Understand the operation of circuit breakers, when to perform routine circuit breaker tests

· Interpret test results, case studies, and numerous field examples

· Effectively create test plans using the manufacturer’s circuit breaker specifications

· Confidently use Vanguard circuit breaker analyzers and VCBA S2 software to perform routine circuit breaker tests and manage test plans and test results

If you have any questions or wish to schedule a custom training at your facility, please contact us.