Before we begin talking about SF6 emissions, let’s get a better understanding of Sulfur hexafluoride. SF6 is an inert, manmade gas composed of one Sulphur and six fluoride atoms. It is odorless, colorless, and chemically inert. It is also non-flammable and has a higher density than air. The high density of SF6 gas makes it vibrate more slowly across your vocal cords, so when it’s inhaled, your voice will sound very low and deep. Though the pure gas is non-toxic, it can irritate the lungs and vocal cords. Additionally, SF6 can contain dangerous acid vapors and cause serious health risks if inhaled, so please don’t try at home. Finally, as you’ll learn in a bit, SF6 emissions (even from a balloon) should be avoided at all costs.

SF6 has an extremely stable molecular structure, requiring a high temperature (up to 500oC ) to break its bonds. Even if the bonds are broken during, say, an arcing event, SF6 will mostly recombine. You can read more about SF6 gas and its properties here. These properties make it an excellent dielectric and its high thermal conductivity make it more effective than air, nitrogen, or other dielectrics at dissipating heat. SF6 has been used as a dielectric in gas-insulated substations and switchgear since the 1950s.

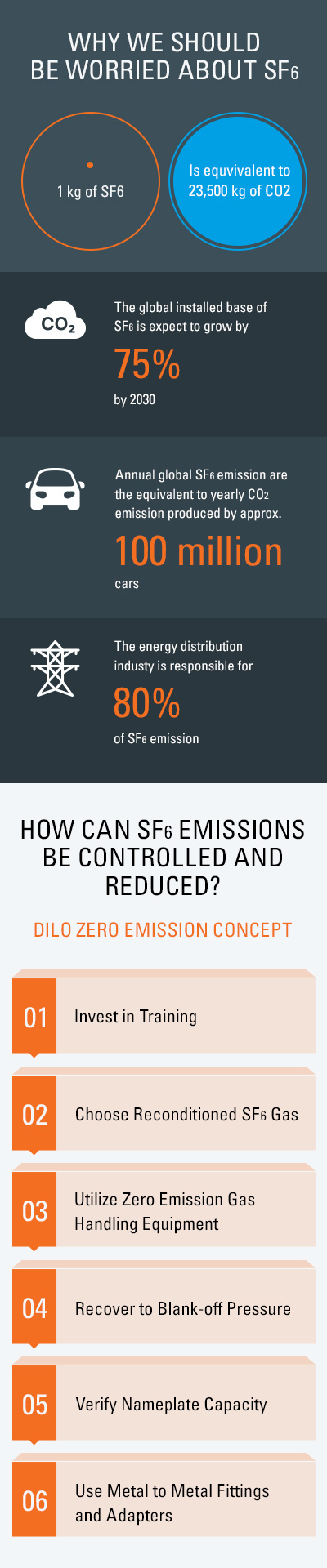

That all sounds pretty good, right? Well, the same properties that make SF6 such a perfect dielectric also make it the most potent greenhouse gas. SF6 emissions are serious because SF6 gas is 22,800 times more effective at trapping infrared radiation over a 100-year period than the more famous greenhouse gas, CO2. Although SF6 emissions make up a small proportion of greenhouse gases found in the atmosphere, controlling SF6 emissions is so important because of its lifespan of 3,200 years. Even a small amount emitted into the atmosphere has a significant impact on climate change.

SF6 Emissions by Sector

In order to reduce SF6 emissions, we must learn what industries are the main users and emitters of SF6 gas. SF6 is used in various industries, including the manufacture of electronics and semiconductors, the production of magnesium, and medical applications such as eye surgery. The largest proportion of SF6 emissions by sector goes to the Transmission & Distribution industry. Global SF₆ emissions have increased by approximately 260% since 1978, with cumulative emissions through 2018 totaling 234 Gg, equivalent to 5,500 Tg CO₂.

It is estimated that the T&D industry uses around 80% of the SF6 gas manufactured and is therefore responsible for a large majority of the SF6 emissions found in our atmosphere. In fact, the EPA estimates that around 71% of all SF6 emissions in the United States are attributed to the electrical transmission and distribution industry.

The Most Common Causes of High SF6 Emissions

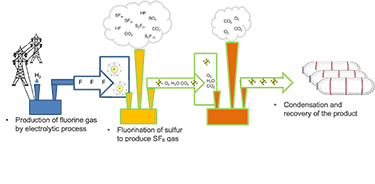

- Virgin SF₆ Gas Production and Importation: One of the causes of SF6 emissions in the T&D industry stems from the sourcing of the gas. The production of virgin SF6 gas is a known source of emissions and must be imported from countries that have not banned its manufacture, such as parts of Eastern Europe and China. Producing virgin SF₆ gas can result in emissions that are 12.5 times higher than reconditioning existing gas for reuse.

- Faulty or Leaking Gas Insulated Equipment (GIE): Properly maintained SF6 GIE has a lifespan of more than 30-40 years. Overtime, GIE can become compromised and begin to leak SF6 gas into the atmosphere. Gas-insulated switchgear (GIS) can have leak rates up to 1% per year, leading to significant SF₆ emissions over the equipment's lifespan. Common issues include worn bushings, seals, tubing, and manifolds, which can create leaks if not promptly identified and repaired.

- Improper SF6 Gas Handling Methods: Our late CEO, Lukas Rothlisberger, used to say that our industry does not have an SF6 gas problem but rather an SF6 gas HANDLING Problem. While it cannot be disputed that SF6 gas is a potent greenhouse gas, there should be little to no emissions to the atmosphere when proper steps are taken during gas handling.

- GIE Nameplate Inaccuracy and “Phantom Emissions”: With emission reporting now being mandatory for many SF6 users, reports of nameplate discrepancies have become quite common. Across the industry both SF6 users and regulatory agencies alike are faced with the difficulty of trying to gather accurate data. When the nameplate capacity of the breaker is incorrect, this can result in either negative or “phantom emissions”. For example, if the actual value is 300 lbs and the nameplate is 280 lbs, there will be a negative emission of 20 lbs. Conversely, if the true value is 280 lbs and the nameplate is 300 lbs, there will be a “phanotom emission” of 20 lbs.

- Inadequate Leak Detection and Repair Strategies: Lack of proactive leak detection and repair strategies can lead to unnoticed SF₆ leaks. Implementing regular inspections using technologies such as thermal imaging and gas density monitoring can help identify and address leaks promptly.

Tips for Reducing and Controlling SF6 Emissions

According to the Intergovernmental Panel on Climate Change (IPCC), SF₆ has a global warming potential (GWP) of 23,500 times greater than CO₂ over a 100-year period.

Regulatory agencies such as the Environmental Protection Agency (EPA) and the California Air and Resources Board (CARB) have begun imposing regulations on SF6 gas and to reduce SF6 emissions. Whether or not your company is affected, you can start taking steps to reduce emissions, which will save your company money and help the environment. Below are some basic tips on how to reduce SF6 emissions:

1. Invest in Training: Well-trained technicians are the first line of defense against SF6 emissions. There is no substitute for knowing how to properly operate SF6 gas handling eqipment. According to the EPA, “Employees involved in handling gas should be specifically trained in SF6 handling and using equipment for performing this task on a routine basis (e.g., annual refresher training)”. DILO offers both virtual and in-person SF6 Safety and Handling Training to help keep your staff up to date on best practices and the latest regulations.

2. Utilize Zero-Emission Gas Handling Equipment: Using the right tools for the job is half the battle. Implementing best practices and utilizing zero-emission gas handling equipment can reduce SF₆ emissions by over 90% compared to older manual systems. Be sure that you’re using appropriate leak detection equipment in the field and consider a room monitor system for indoor Gas Insulated Substation (GIS) applications. Utilize a measuring device that has an internal recovery feature or is compatible with a recovery bag to avoid venting SF6 to the atmosphere during testing. It’s also important to use the correct size and type of recovery unit for the volume of SF6 gas you’re working with. Our SF6 Time Calculation App can help you determine which gas cart is suitable for your application.

3. Choose Reconditioned SF6 Gas: As mentioned earlier, sourcing virgin SF6 gas contributes to SF6 emissions. Luckily, SF6 gas that has been reconditioned to meet or exceed IEEE standards can be used in place of virgin gas in applications for the T&D industry. Another bonus is that sourcing reconditioned SF6 is usually much less expensive than purchasing virgin gas. DILO team members have written a few articles on reconditioned SF6 gas if you’d like more information. It’s important that you select a vendor who conducts 3rd party testing to verify that the gas has been reconditioned to meet or exceed IEEE standards, thereby making it safe to use in Gas Insulated Equipment (GIE).

4. Recover to Blank-Off Pressure: Be sure to reach the lowest level of vacuum or blank-off pressure possible during SF6 gas recovery. If the amount of gas in GIE is reduced to atmospheric pressure, a startling 20% of residual gas is left inside. This creates a high potential for an SF6 emission.

5. Verify Nameplate Capacity: Check the OEM’s manual or nameplate for accurate SF6 capacity information. Overfilling GIE can result in SF6 emissions by engaging the pressure relief valve. Using a mass flow meter or cylinder weight scale to track SF6 gas movements is also helpful and can prevent any errors that may result in “phantom emissions”. Ensure that your mass flow meter is capable of measuring liquid SF6 gas. We have an excellent white paper, SF6 Nameplate Inaccuracies and their Impact on Greenhouse Gas Reporting, that covers this topic in more detail.

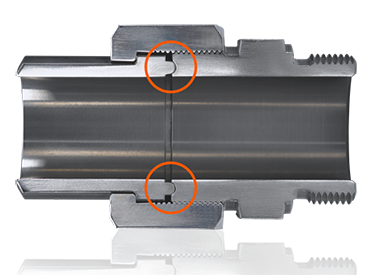

6. Use Proper Fittings and Adapters: Ensure fittings used for connection to GIE and other accessories (manifolds, analyzers, cylinders, etc.) are leak tested. Refrain from using threaded connections, which are prone to leak over time. Metal to metal sealing technology is best for SF6 gas handling.

7. Implement a Lifecycle Approach for SF₆ Management: Establishing company policies, protocols, and standard operating procedures for SF₆ management helps track inventory and costs, detect and repair leaks, and properly handle, recover, and recycle SF₆. This approach ensures continuous improvement and expansion to incorporate other options for reducing SF₆ emissions.

8. Upgrade Equipment to SF₆-Free Alternatives: New equipment designs use less SF₆ and tighter seals to reduce leaks. Other designs use alternatives to SF₆, like vacuum-based technology with CO₂ or “Clean Air” as a base gas. Upgrading to such equipment can significantly reduce SF₆ emissions.

9. Decommission Equipment Properly:

When retiring or replacing gas-insulated switchgear or other SF₆-containing assets, ensure that all SF₆ gas is recovered and either reconditioned or destroyed at an approved facility. Improper disposal can result in uncontrolled emissions. Implement formal end-of-life procedures that include leak testing, documentation, and recovery tracking.

10. Monitor Input Delay and Gas Pressure in Real Time:

Advanced monitoring tools that track input delay and SF₆ pressure variations can help detect potential leaks early. Integrating sensors that feed data to a centralized system allows operators to respond faster to abnormal readings, preventing unnecessary emissions.

The above is not an exhaustive list- we could spend all day writing and talking about ways to reduce SF6 emissions and still have more to say. For a more in-depth experience, we suggest you check out our SF6 Safety and Handling Trainings. We can even come to your facility to train your entire team on how to reduce SF6 emissions. Please contact us if you have any questions or receive more information on custom training at your facility.