SF6 Gas Analyzer Calibration Service | DILO Inc.

Gas analyzers are essential to the safety and success of many industries, from manufacturing to in-service field use, to research facilities. These instruments help businesses analyze the concentration and quality of compounds within a gas or gas mixture.

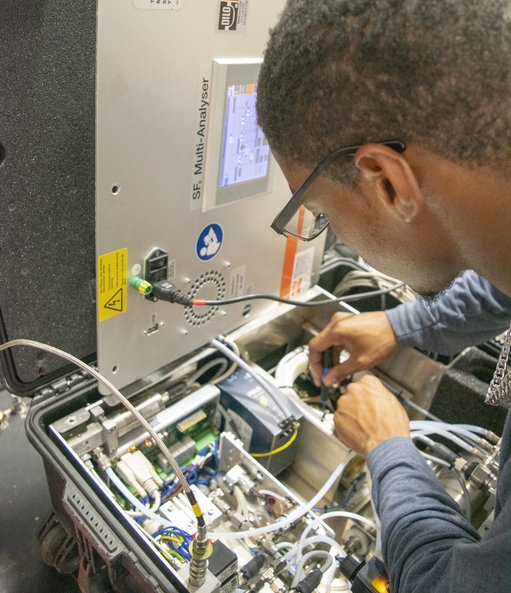

For analyzers to function optimally, periodic calibration is necessary. With SF6 gas handling, frequent calibration empowers more accurate readings and zero emissions of SF6 gas. In addition to an innovative SF6 gas analyzer, DILO offers gas analyzer calibration service from certified technicians to ensure the lasting use of your gas handling equipment.

Analyzers should be calibrated at least every two years to ensure zero emissions of SF6 and accurate readings. The recommended calibration time of two years is based on average use. If you receive a lifetime of sensors expired warning, you should send the analyzer in for calibration immediately. Regular, preventative maintenance will extend the life of your analyzer. It is important that a well-qualified technician performs the calibration. Improper calibration could result in exposure to arc by products, damage to the unit, or faulty readings during gas analysis. When you send your unit into DILO’s Analyzer Calibration Laboratory, a certified technician will:

- Perform initial inspection functional test for the unit and accessories, including sensors, operating software, batteries, hoses, and fittings

- Leak test the entire unit

- Review the service history of the device

- Update operating software, if applicable

- Provide an estimate and lead time for any additional repairs upgrades, if applicable

- Obtain customer approval before starting any additional repairs

- Safely neutralize and dispose of any items exposed to Arc-byproducts

- Perform sensor and module calibration/exchange, including SO2 sensor, purity sensor, moisture sensor, and electrochemical sensor

- Provide third party calibration certificate

- Replace any missing manuals

Why DILO?

Although some users attempt gas analyzer calibration on their own, it’s best to seek assistance from qualified professionals. DILO Certified technicians have years of experience with analyzer calibration and undergo regular training to enhance their skills. They also use cutting-edge testing equipment to ensure more precise evaluations. What’s more, our calibration services provide a third-party certification for assurance.

Consider some of the services DILO’s technicians provide:

- Test units in their current state to understand how they have performed in the field most recently

- Adjust analyzers that are out of tolerance

- Properly interpret results

- Identify false positive results

Another reason to choose DILO’s gas analyzer calibration service is that certified technicians can spot other issues with your equipment during evaluations. For example, technicians have noticed transport cases with worn-out wheels and contaminants inside devices that users may not have detected otherwise.

If your gas analyzer is older than 10 years, calibration will no longer help; replacement is necessary. DILO considers the needs of all customers and offers a legacy trade-in program* for those with outdated equipment.

Commitment to Reducing Lead Times

DILO continually strives to improve maintenance services. We recognize the importance of limited downtime for our customers, whose businesses rely on steady production.

With our services, we strive to reduce and maintain service lead times at all costs. We’ve implemented several methods to minimize lead times:

- Increased our number of workstations and stock of common parts

- Increased training for technicians

- Increased stock of common parts

- Simplified the RMA process

- Reduced processing times

- Created Direct Connect Services to field level inspect equipment before having to send it out for services.

- Introduced slot planning and fixed booking of services

- Send courtesy service reminder emails so customers can prepare for service

Types of Gas Analyzers We Calibrate

DILO provides calibration service for the various types of gas analyzers we sell, including:

Multi-AnalyzerSF6

The Multi-AnalyzerSF6 is an emission-free gas analyzer capable of measuring up to six specifications within a single sample. It calculates moisture measurements at operating pressure, giving users exceptionally high accuracy. Direct Connect hardware enables remote analyzer access by DILO technicians for swift troubleshooting.

Mirror AnalyzerSF6

The Mirror AnalyzerSF6 enables users to determine up to three parameters with only one measurement. These parameters include moisture concentration, SF6 volume percentage, and SO2 concentration.

Arc-Byproducts Analyzer

The breakdown of decomposition products, such as SO2 and SOF2, may occur after operating gas-insulated switchgear, making measuring these products crucial. DILO offers an arc-byproducts analyzer with a rapid response time and rechargeable battery.

Moisture Analyzer

Moisture is key for establishing the quality of a gas. Our moisture analyzer is created specifically for measuring SF6 gas moisture. The reliable device has indicated greater resistance to contamination when compared with conventional moisture sensors.

Why Is Gas Analyzer Calibration Important?

Gas analyzers are critical for many important processes. Understanding the quality of gas before and after equipment is put into operation is essential for the performance of the equipment. In addition, companies need properly functioning analyzers to ensure the wellbeing of employees working with or around these gases. The United States Occupational Safety and Health Administration (OSHA) compiles chemical hazards and toxic substances in workplaces that may impact human health. Regular calibration ensures analyzers can detect the presence of dangerous concentrations of certain gases and warn businesses of the potential threat to worker health.

Difference Between Calibration and Other Gas Analyzer Maintenance Services

While calibration is an important part of gas analyzer maintenance, it’s not the only service these devices may need. The frequency of calibration differs depending on specific sensor technology parameters, but it’s always required following gas analyzer repair.

Verification is another aspect of maintenance and involves evaluating analyzers to ensure they provide accurate measurements under normal operations. DILO certified technicians compare analyzer readings to highly accurate precision tools. Verification dictates whether immediate action is needed to correct any issues.

Routine maintenance of gas analyzers includes any activities that preserve the functionality of your equipment. It encompasses corrective and preventive measures like cleaning, software updates, adjustments, and replacement. DILO technicians can guide you on how often you should conduct routine maintenance based on the application and usage.

Seek Gas Analyzer Calibration from DILO

DILO is a leading partner in emission-free gas handling for global customers and we offer a range of SF6 gas products and a Direct Service line for professional gas management. In addition to gas analyzer calibration, we provide other after-sales support services like gas cart maintenance and annual scale calibration.

Partnering with DILO means gaining innovative solutions that meet the many challenges of gas handling and equipment designed for maximum efficiency, putting our customers at a technological advantage. Dedicated to excellent customer service, DILO gives businesses peace of mind about gas handling. To learn more about our gas analyzer calibration service or other offerings, contact us or fill out an RMA request form to get started today.