SF6 Gas Disposal and Recycling

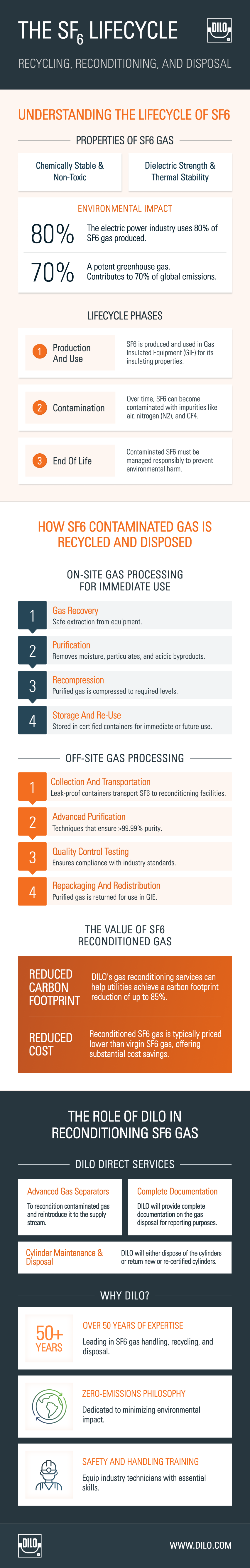

Sulfur hexafluoride (SF6) is a chemically stable, non-toxic gas with exceptional dielectric strength and thermal stability. These properties make it the preferred choice for insulating high-voltage electrical equipment like transformers and switchgear (GIS). However, there's a critical aspect to consider: SF6 is also a potent greenhouse gas. The Environmental Protection Agency estimates the electric power industry uses about 80% of all SF6 gas produced worldwide and is responsible for about 70% of global SF6 emissions.

At DILO Direct, we are committed to helping utilities worldwide navigate the complexities of SF6 gas management throughout its lifecycle. We offer a comprehensive suite of services designed to minimize environmental impact while ensuring the continued safe and reliable operation of gas-insulated equipment on the electrical grid.

Second Life, Same Performance - Optimizing Your SF6 Footprint

Our SF6 gas management approach prioritizes recycling and reconditioning whenever possible. We begin by analyzing your used SF6 gas for contaminants like air, nitrogen (N2), carbon tetrafluoride (CF4), moisture (H2O), oils, and arc-byproducts (SO2). If the gas is suitable, we can recondition it using our advanced gas separation and preparation technology. This multi-stage process removes impurities, ensuring the reconditioned gas meets or exceeds industry standards for purity (e.g., IEEE (Institute of Electrical and Electronics Engineers) and IEC (International Electrotechnical Commission) and can be safely reused in your Gas Insulated Equipment (GIE).

The SF6 Recycling Process Explained

The term "recycling" encompasses both on-site gas processing for immediate reuse and off-site reconditioning facilities. Both methods share the core objective of removing contaminants and ensuring the gas meets the necessary purity levels for safe and reliable operation within electrical equipment.

On-Site Gas Processing for Immediate Re-Use: On-site processing offers a convenient and efficient solution for reusing SF6 gas directly at the point of extraction from GIE. This approach minimizes downtime, transportation costs, and overall gas management complexity. Here's a breakdown of the on-site processing steps:

- Gas Recovery: Specialized compressor systems safely extract the insulating gas from the equipment, preventing atmospheric release during the gas recovery process.

- Gas Drying: The recovered gas undergoes a multi-stage drying process to eliminate contaminants like moisture (via desiccant dryers), particulates (through filtration), and acidic byproducts.j

- Recompression: The gas is then consolidated and compressed using oil-free compressors designed for safe and efficient handling of SF6.

- Storage and Re-Use: The processed gas is stored in certified containers until ready for reuse. It can be immediately reinjected into the GIE or stockpiled for future use depending on operational needs.

Off-Site Reconditioning Process for Insulating Gases: Off-site reconditioning is ideal for situations where on-site processing is not feasible due to space limitations, equipment requirements, or the need for exceptionally high purification levels. Here's a closer look at the off-site reconditioning process:

- Collection and Transportation: The insulating gas is collected from various locations using specialized, gas recovery equipment, and leak-proof containers so that it can be transported to a dedicated reconditioning facility adhering to stringent safety regulations.

- Advanced Purification: At the facility, the gas undergoes a multi-stage purification process. This may include techniques like multimedia filtration, chemical absorption, and cryogenic distillation to achieve maximum purity levels exceeding >99.00% SF6 concentration.

- Quality Control Testing: Following purification, rigorous quality control testing ensures the gas meets or exceeds industry standards for purity, moisture content, and decomposition product levels. This guarantees reliable performance when reintroduced into your GIE.

- Repackaging and Redistribution: The purified gas is then transferred into certified containers and transported back to the original site or other locations for immediate use in GIE.

The Value of Reconditioned SF6 Gas

Our commitment to sustainable SF6 gas management extends to offering you environmentally and economically responsible solutions. Here's how reconditioned SF6 gas delivers significant benefits for your utility:

- Reduced Carbon Footprint: Virgin SF6 gas production is a significant contributor to greenhouse gas emissions. By choosing reconditioned SF6 gas, you're actively reducing your environmental impact. Studies by CBM report that DILO's gas reconditioning services can help utilities achieve a carbon footprint reduction of up to 85%. This translates to a smaller environmental footprint for your electricity generation and distribution operations.

- Reduced Costs: Reconditioned SF6 gas is typically priced lower than virgin SF6 gas, offering substantial cost savings for your utility. This can significantly impact your overall budget while promoting responsible environmental practices.

DILO Direct Services

At DILO, we’re committed to high-quality service and best-in-class equipment to live up to our responsibility for environmental protection. We use our DILO SF6 gas separators to recondition contaminated gas and reintroduce it to the supply stream. Following the reconditioning and disposal process, we will either dispose of the cylinders or return new or re-certified cylinders. DILO Direct will receive the gas, document the quantity received, and provide complete documentation on the gas disposal for reporting purposes.

Why DILO: A Leader in SF6 Gas Handling, Recycling, and Disposal

With over 50 years of experience in SF6 technology, our customers know they can count on DILO for professional and emission-free gas handling. Our zero emissions philosophy is reflected in our comprehensive services for SF6 and alternative gasses.

In addition to SF6 recycling, DILO offers safety and handling training for industry technicians. We also offer numerous other gas handling services, such as leak detection, true mass monitoring, cylinder maintenance, SF6 reconditioning, and power circuit breaker electrical testing.

A family-operated organization with a global presence, DILO is committed to delivering excellent customer service and powering innovation to tackle current and future challenges. To learn more about our cost-effective and sustainable SF6 disposal solutions, contact us or complete the RMA request form today.

RMA Form