IEC specifications (standards) for sulphur hexafluoride

What Are the IEC Standards and Specs for SF6 Gas?

At DILO, we are committed to providing sustainable, environmentally friendly solutions for the professional handling of gases. With locations in Florida, Arizona, and Oregon, DILO provides certified sulfur hexafluoride (SF6) gas, high-quality industrial gas equipment, and testing, monitoring, and disposal services. We hold ourselves to the highest SF6 gas specifications and standards to give our customers the utmost confidence in our products.

What is the IEC?

The International Electrotechnical Commission (IEC) is a global organization that sets standards for electrical and electronic technologies and related materials. First founded in 1906, the IEC is comprised of 89 member countries and dozens of affiliate countries. Many member countries adopt IEC’s standards as their national standards, some of which are developed jointly with the International Organization for Standardization (ISO).

What Is Included in the SF6 Gas Standards and Requirements?

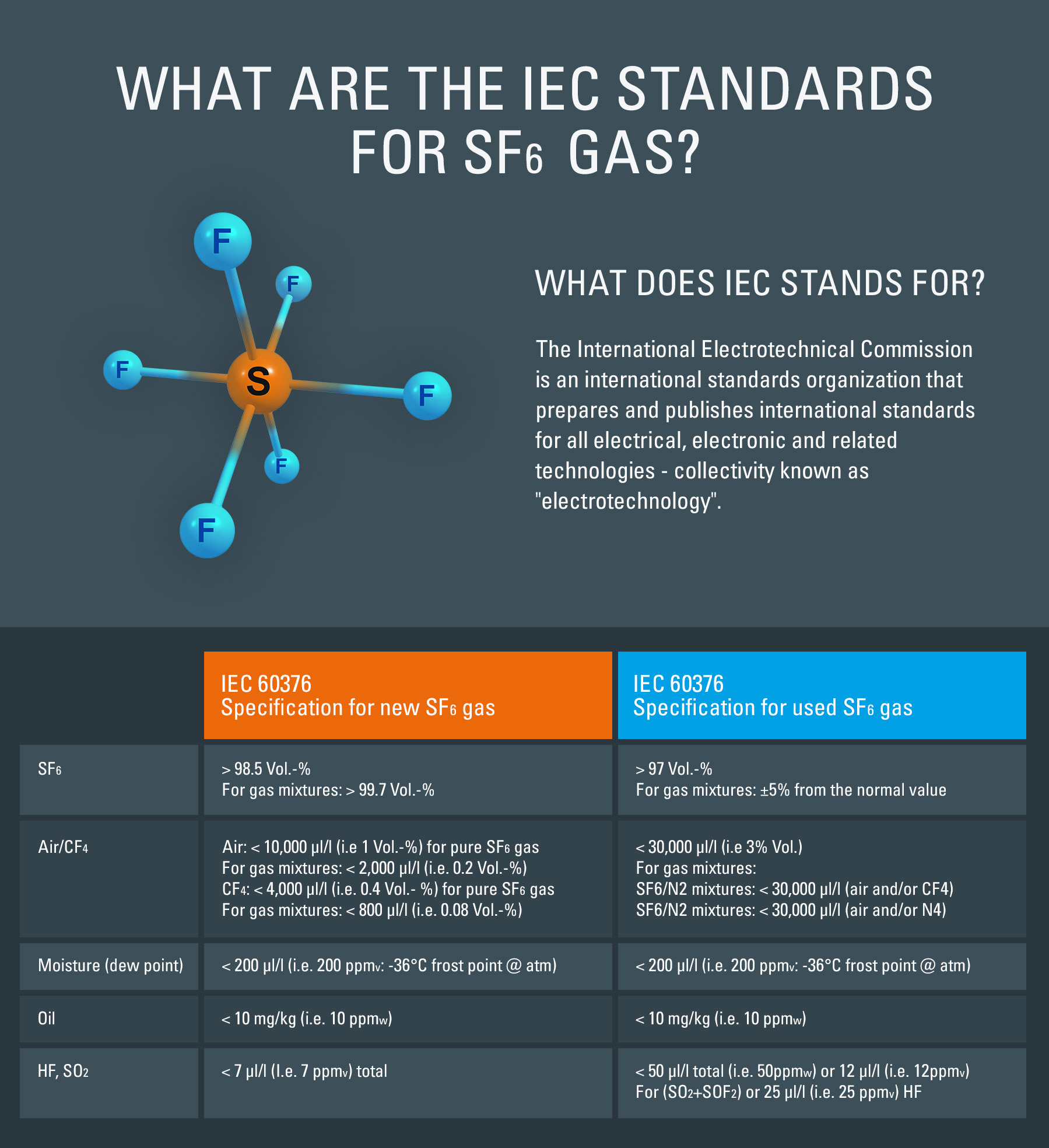

IEC sets specifications for both new and used SF6 gas. IEC 60480 is the standard that provides criteria for the re-use of SF6 gas, while IEC 60376 defines the quality for technical-grade SF6 gas, as well as complementary gases, including nitrogen (N2) and carbon tetrafluoride (CF4).

These international standards cover several essential aspects, such as:

- SF6 Requirements specific to secure handling, storage, and transportation

- Potential contaminants and their sources

- Specifications for the re-use of SF6

- Methods of analysis for SF6 gas

- Decomposition and behavior of SF6 gas

- Neutralizing solutions

- Safety and first aid

What are the Requirements for Safe Handling and Storage of SF6?

Precautions for Safe SF6 Handling

- Wear leather safety gloves and safety shoes when handling cylinders.

- Protect cylinders from physical damage; do not drag, roll, slide, or drop.

- While moving the cylinder, always keep in place the removable valve cover.

- Never attempt to lift a cylinder by its cap; the cap is intended solely to protect the valve.

- When moving cylinders, even for short distances, use a cart (trolley, hand truck, etc.) designed to transport cylinders.

- Never insert an object (e.g., wrench, screwdriver, pry bar) into cap openings; doing so may damage the valve and cause a leak.

- Use an adjustable strap wrench to remove over-tight or rusted caps.

- Slowly open the valve. If the valve is hard to open, discontinue use and contact your supplier.

- Close the container valve after each use; keep closed even when empty.

- Never apply flame or localized heat directly to any part of the container. High temperatures may damage the container and could cause the pressure relief device to fail prematurely, venting the container contents.

Precautions for Safe SF6 Storage

- Store in a cool, well-ventilated place.

- Store and use with adequate ventilation.

- Store only where the temperature will not exceed 125°F (52°C).

- Firmly secure containers upright to keep them from falling or being knocked over.

- Install the cylinder valve protection cap if provided, firmly in place by hand.

- Store full and empty cylinders separately.

- Use a first-in, first-out inventory system to prevent storing full containers for long periods

- When handling the product under pressure, use piping and equipment adequately designed to withstand the pressures to be encountered.

- Never work on a pressurized system.

- Use a backflow prevention device in the piping.

- Gases can cause rapid suffocation due to oxygen deficiency; store and use with adequate ventilation.

- If a leak occurs, close the container valve and blow down the system in a safe and environmentally correct manner in compliance with all international, federal/national, state/provincial, and local laws

SF6 gas is one of the six greenhouse gases that must be monitored following the Kyoto protocol. To avoid emissions, SF6 must be used in closed systems.

Choose DILO for Certified SF6 Gas

At DILO, we are an industry leader in responsible gas handling and safety. Using rigorous testing procedures, we guarantee each cylinder of SF6 gas provided by our company has the following:

- <99.5 ppmV (-41.5⸰ dew point) moisture content

- >99% SF6 purity

- Zero SO2 / gas byproducts

Headquartered in Odessa, Florida, DILO provides certified SF6 gas to customers throughout the United States, Canada, Latin America, and the Caribbean. DILO’s SF6 gas exceeds the IEC 60480 standard, as well as the Institute of Electrical and Electronics Engineers’ standard for SF6 gas handling (IEEE C37.122.3-2011). For more information about us and the current SF6 gas standards.