Legacy Equipment Program

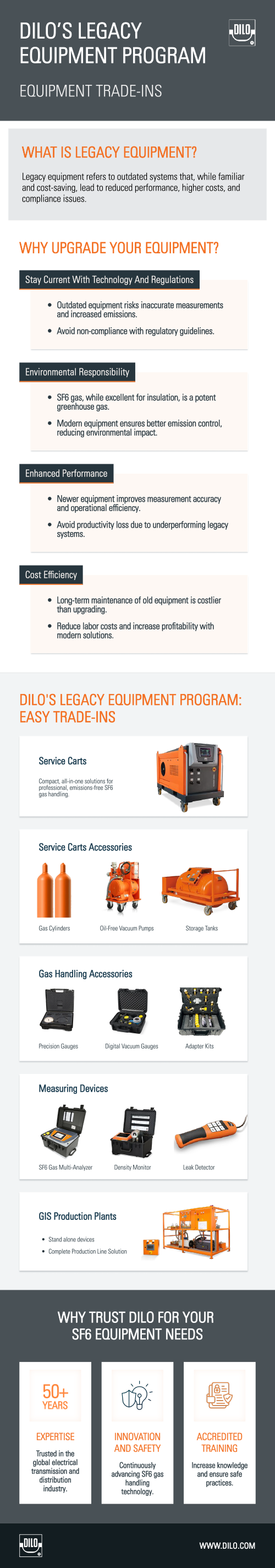

SF6 Gas Equipment Trade-In

For those in the electrical transmission and distribution industry, keeping up with technological advancements and regulatory guidelines is crucial. Many organizations use sulfur hexafluoride gas (SF6 gas) for high-voltage applications because of its superior insulating properties. However, when companies fail to update their equipment, there is a risk of inaccurate measurements, increased emissions, and consequences from regulatory bodies.

Luckily, DILO offers a solution with the legacy equipment program. Part of our after-sales support and services, this program provides easy SF6 gas equipment trade-in. By upgrading your SF6 equipment, you receive better performance for emissions-free gas handling. Organizations worldwide, from government energy sectors to private utilities and gas-insulated equipment OEMs, trust DILO for quality SF6 gas equipment products and services.

What is legacy equipment, and why should it be replaced?

As organizations seek to modernize processes as technology advances, a major focus is updating systems and equipment. This can be challenging, as employees are more familiar with the existing applications, devices, and processes for everyday tasks. Businesses continue using these outdated “legacy” equipment and systems, even when updated versions are available to save on equipment costs, avoid training, and to preserve existing procedures. However, maintaining legacy equipment instead of updating it can lead to a drop in performance, higher costs, and compliance issues.

The Negatives of Outdated Equipment

In addition to legacy systems still powering daily functions, other reasons an organization may continue using them are cost and complexity.

The long-term costs of maintaining legacy systems are higher, but the upfront costs of replacement are steep. Businesses also often consider the cost of training employees in the new equipment. Companies often also consider transitioning from legacy equipment to new devices a complex undertaking.

These concerns are valid, but businesses should know continuing with legacy equipment poses several drawbacks. These include:

Less-Environmentally Conscious

The properties of SF6 gas make it highly sought after for electrical insulation, semiconductor manufacturing, magnesium production, and more. It’s odorless, colorless, non-toxic, and non-flammable. It also has high dielectric strength and is temperature-resistant up to 500º C.

For all its beneficial attributes, SF6 gas is one of six gases with the most potential for global warming. As such, responsible SF6 gas handling and management are critical to lower environmental impact.

Organizations achieve emissions-free gas handling using specialized equipment and processes. However, when this equipment is outdated, it’s less effective at preventing emissions. Businesses risk not meeting standards from regulators like the U.S. Environmental Protection Agency. They also risk harming the atmosphere.

Reduced Performance

After a while, repair isn’t enough to keep equipment running as well as it once did. SF6 measuring devices may not be as accurate. Service carts may experience wear and tear. Ultimately, under-performing equipment hurts productivity.

Increased Cost to Maintain

The long-term costs of maintaining legacy equipment often outweigh the high upfront costs of replacement. Manufacturers often add new features to equipment following new guidelines about emissions-free gas handling.

Instead of having new equipment with these necessary features, teams using legacy devices must figure out how to ensure compliance and minimize environmental impact on their own. This can increase labor costs as teams must determine how to support legacy systems. A lack of efficiency also reduces profitability.

SF6 Gas Equipment Trade-In/Trade-Up

With DILO’s legacy equipment program, utilities companies and government energy agencies find an easy way to ensure they use updated SF6 gas equipment. Check out some of the SF6 gas products we offer and available models:

- SF6 Gas Filling and evacuating devices: Fill porcelain insulators in outdoor switchgear safely with these devices. The operator can fill using a remote device up to 100 m away for protection against insulator bursts.

- SF6 Service carts: These compact devices have all the functions necessary for professional, emissions-free SF6 gas handling.

- Accessories for SF6 service carts: SF6 gas cylinders, oil-free vacuum pumps, storage tanks, filters — find the service cart accessories you need.

- SF6 Gas handling accessories: Ensure responsible SF6 gas handling with these accessories, which include digital vacuum gauges, precision gauges, and adapter kits, among other items.

- SF6 Mass measurement devices: Achieve accuracy with mass measurements with equipment like mass flow meters and electronic SF6 cylinder weight scales.

- Measuring devices: With these devices, you get precise results for SF6 quality, purity, arc by-products, leak detection, and more.

- Accessories for measuring devices: Accessories like compressors keep measuring devices working as intended.

- Valves and couplings: These SF6 fittings and couplings provide the perfect connection to gas compartments for emissions-free gas handling.

- SF6 Leak testing chambers: Experience more accuracy with leak detection using these devices.

- GIS production plants: DILO offers specialized equipment for gas-insulated applications, including switchgear (GIS), lines (GIL), and transformers (GIT).

- Special applications: Find units for handling SF6 gas mixtures and related applications.

DILO also offers after-sales support to help maintain SF6 equipment and extend service use. This includes gas cart maintenance programs for small and large carts, analyzer and scale calibration, and other refurbishments/upgrades. You can also access various gas handling services through DILO Direct.

Trust DILO for Your SF6 Equipment Needs

The global electrical transmission and distribution industry has trusted DILO with emissions-free gas handling for over 50 years. We innovate constantly to offer SF6 gas and related products that enable your organization to operate more safely and efficiently while maintaining a technological advantage. DILO also helps increase knowledge of SF6 gas handling through accredited training.

Interested in an SF6 gas recovery equipment trade-in? Contact us today to speak with a regional sales manager about our legacy equipment program.