When working with sulfur hexafluoride (SF6), performing duties under the compliance of regular modern safety standards and gas emission control is critical. This six-part blog series touches on the industry’s various maintenance and safety tips, highlighting the maintenance of measuring equipment, gas service carts, and gas-handling accessories, as well as the importance of professional calibration of measuring instruments.

DILO is the leading provider of SF6 equipment supply and gas handling services for various industries. We offer quality, long-lasting products and services combined with unmatched customer service. Our team is here to ensure you have the tooling and technical support for all aspects of gas handling. This new blog post series helps to call attention to the importance of maintaining your equipment while relying on DILO’s years of experience.

In the first post of this series, we will help identify what steps need to be taken and when to maintain your SF6 service handling equipment properly. We discuss the What, Why, When, and How to keep your gas-handling fleet operating at peak performance.

Why SF6 Service Equipment Maintenance Matters

Sulfur hexafluoride (SF6) gas is an essential insulating medium for medium and high-voltage electrical equipment. It also has many other special applications, such as its use as an etching gas in semiconductor manufacturing or as a blanket gas for magnesium production.

However, SF6 gas is a greenhouse gas and has proven to be harmful to the environment. Many technologies are designed to control the emissions of SF6 gas and to promote greener gas handling techniques. Equipment must be designed and maintained to ensure consistent gas quality and zero emissions.

How Often Should Gas Service Equipment Be Maintained?

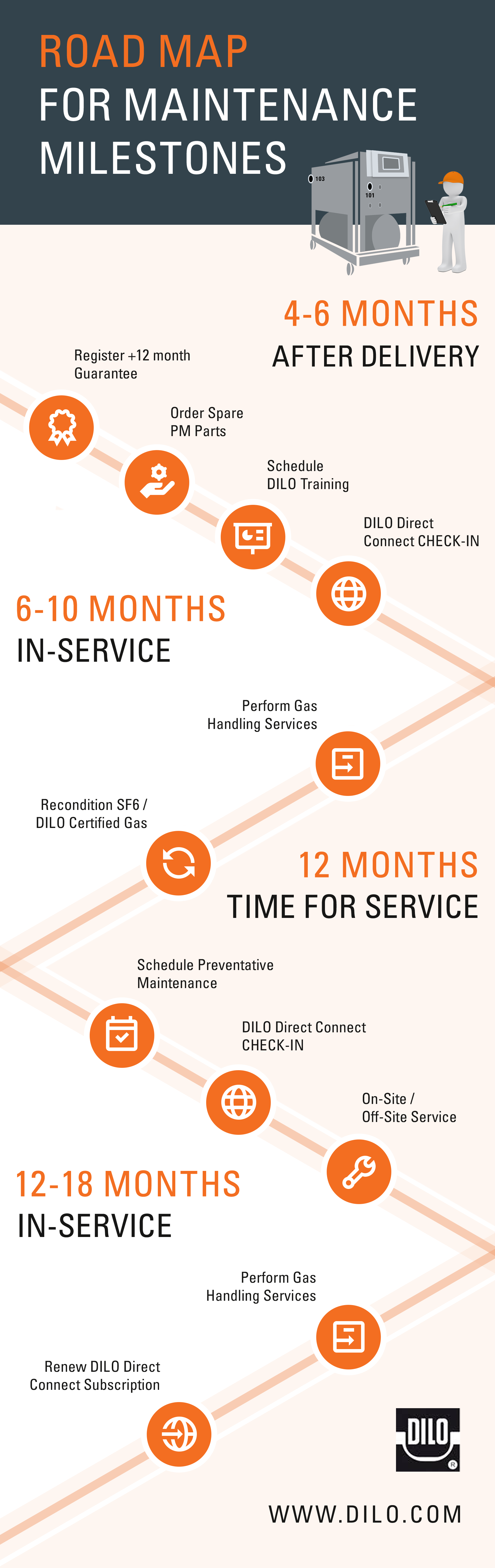

It all comes down to frequency and maintaining a routine for the best results. The frequency can vary depending on the equipment’s type, size, and usage. But even more essential is staying on schedule and establishing an unvarying service routine. Fortunately, DILO is here to help provide a road map to fall back on if you go off track:

Four to Six Months After Delivery

Soon after receiving your equipment, you should register the product for a free +12-month guarantee. It is a quick and easy step that ensures your equipment is protected from the minute it arrives at your establishment. DILO equipment comes with a standard 12-month warranty,and with the addition of the +12 month guarantee, you have taken the step to lock in 24 months of protection.

The next step is to schedule a DILO training. At no additional charge, we will help to organize a hands-on operational training session on your new equipment for your staff. Ensuring your service team has the skills to confidently operate the equipment while preventing emissions and safely work with SF6 gas is a top priority for us. While on-site providing training, we will also take the time to introduce your team to DILO Direct Connect, the device's gateway back to DILO’s technical experts, who are ready to assist when you are in the field.

DILO Direct Connect is a router installed in the device that allows DILO to connect to the equipment remotely and offer operational or technical assistance as you run the equipment. Lastly, our training services help cover all aspects of the equipment accessories and important information on how, when and what maintenance services are required over time.

Don't forget to check out DILO’s exclusive online training, DILO Academy, for additional training options.

Within four to six months after setting up your equipment, you should also consider being prepared with spare maintenance parts on hand. Depending on usage, the 1st round of maintenance services is required within 10-12 months of field usage.

The six month mark is an excellent time to CHECK-IN with your DILO Direct Connect system. This is an important step in establishing a good routine. Remember, there is no additional charge for using DILO Direct Connect. When you utilize Direct Connect, we take the time to offer a quick spot-check of the system's condition and provide you with pointers as you become familiar with the new equipment.

Six to Ten Months of In-Service

This is when the new equipment will get a lot of field usage. Now that your team is well-trained and familiar with the equipment, and they have DILO in their back pocket with DILO Direct Connect, it is time to put the equipment in use for emission-free SF6 gas handling.

While performing gas handling services, you will not only have the peace of mind knowing DILO equipment is designed to prevent gas emissions, but if you ever have any questions or happen to forget which button to press, you don't have to worry about searching around for a manual. Instead, use DILO Direct Connect and we will help assist you with the solution!

With your equipment in service, performing gas filling or gas recovery, there is one other important maintenance consideration you will need to keep in mind. This step is not for the gas handling equipment- it is for the gas quality itself!

Gas handling carts are designed with filtration systems, but sometimes, depending on the gas quality or gas volume, an additional pre-filter system may be required. Maintaining the gas quality is a crucial element of the gas handling process. If the gas is contaminated with air and you notice the purity of the gas is too low, there is no need to worry. It is possible to recondition the gas to usable standards. If you cannot recycle the gas in the field, it can be sent off to your gas supplier for reconditioning services.

It is essential to test the gas quality before you begin any gas transfer process, during, and after you fill equipment. If you do not have the necessary equipment to test the gas, calling a professional to carry out these services will ensure that the gas is processed correctly and safely. If your stock of SF6 gas has been contaminated, you can also send it in for reconditioning and/or purchase DILO Certified SF6 Gas.

12 Months After Delivery

After about one year of use, it is time to schedule an annual preventative maintenance service. To do this, connect with DILO via DILO Direct Connect, and we will help advise on the maintenance services required for the particular system you are working with. In taking time for a Direct Connect Check-In, we help ensure your equipment is functioning correctly, we review the system’s operating hours and usage log.

12 to 18 Months In-Service

This is where the timeline begins to renew. At this point, the equipment has been in service and well maintained for its break-in year. You have established a good routine for utilizing DILO Direct Connect and are getting the most of this service DILO provides. Nice work! DILO will help to send out reminder emails, but it is essential to maintain a schedule of routine check-ins and maintenance services.

Additionally, this is the time to consider renewing your DILO Direct Connect subscription. This subscription provides additional resources for users to turn to when operating the gas handling equipment. With it, users know they can receive assistance whenever they need it. It also gives equipment owners quick access to information if something goes wrong with their equipment while in the field and allows DILO to react quickly to resolve any technical concerns. Renewing this subscription will enable you to be prepared for the year ahead.

Get Assistance with Your Gas Handling Equipment

Within many industries, proper equipment maintenance is vital for the safety of the employees, the workplace environment, and the success of a project or business operations.

If you are looking for gas-handling equipment and/or services, you can count on DILO. We ensure that we meet and exceed the standards associated with SF6 gas applications, allowing companies to continue running smooth operations. To learn more about how we can assist in your efforts for sufficient, emission-free SF6 equipment maintenance service, contact us or fill out an RMA request form today.