SF6 Gas Use in the Electric Industry

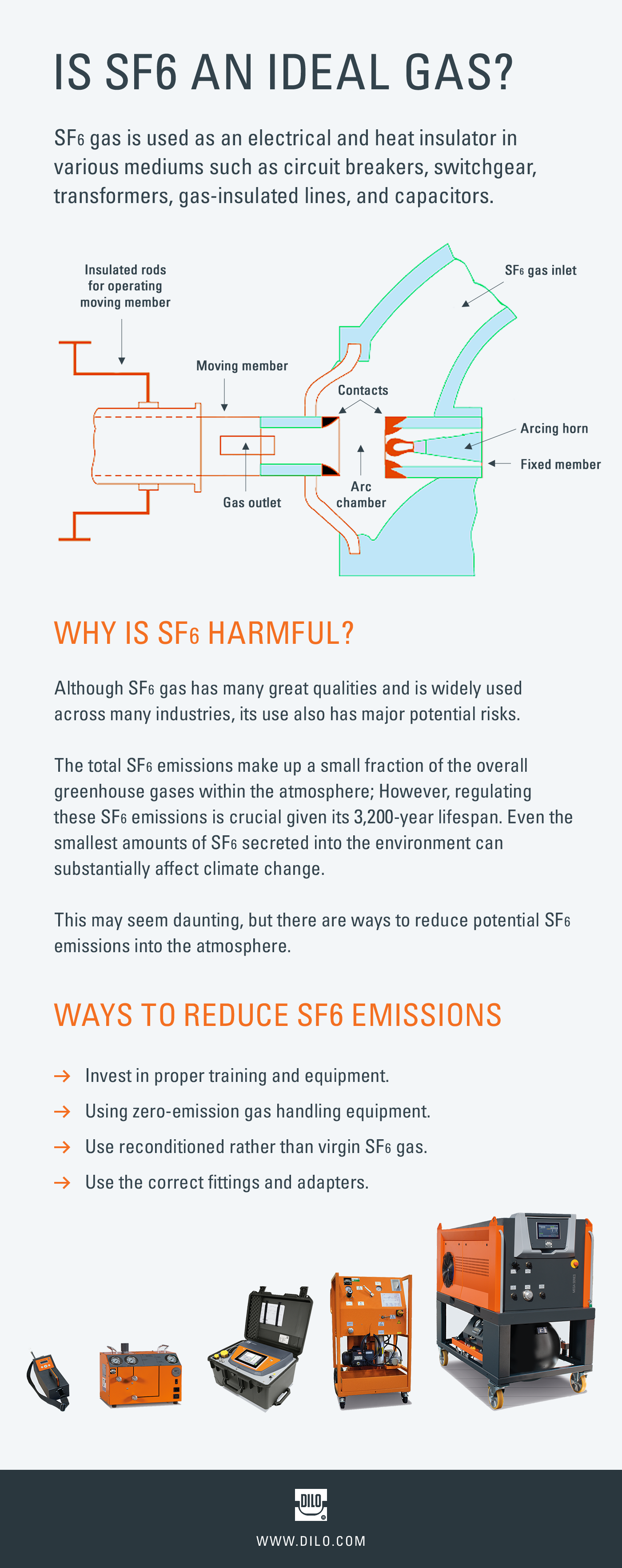

SF6 gas has been used in the electrical industry for over 50 years, as it is non-toxic, thermally stable, and chemically inert. It is routinely used as an electrical and heat insulator in a variety of mediums such as circuit breakers, switchgear, transformers, gas-insulated lines, and capacitors.

Circuit breakers are electrical safety devices that stop electrical streams to safeguard entire power stations and power distribution systems. Some circuit breakers use SF6 gas as it is highly efficient at quenching the arcs that are produced when electrical circuits are open and closed.

Why SF6 Gas Became Popular

In the 1990’s, oil circuit breakers were popular, but their required regular maintenance to handle the pollution and flammability proved to be cumbersome. This concern led to the adoption of SF6 gas circuit breakers into the electrical industry, which proved to leave a smaller footprint compared to the breakers that utilize other insulators. The insulating strength of SF6 actually intensifies with pressure, allowing for the usage of smaller breakers at a higher voltage.

Is SF6 An Ideal Gas?

Although SF6 gas has many great qualities and is widely used across many industries, its use also has major potential risks. SF6 has been named one of the most potent greenhouse gases as it is 24000 times better at trapping heat when compared to CO2, the benchmark gas for determining a gas’s global warming potential (GWP). It is true that the total amount of SF6 emissions makes up a small fraction of the overall greenhouse gases within the atmosphere; However, regulating these SF6 emissions is so crucial given its 3,200-year lifespan. Even the smallest amounts of SF6 secreted into the environment can have a substantial effect on climate change.

The most common causes of SF6 emissions include the production of virgin SF6 gas, faulty or leaking SF6 gas insulated equipment, and improper handling methods. This may seem daunting, but thankfully there are ways in which we can reduce potential SF6 emissions into the atmosphere to help reduce the impact on the environment.

One step in reducing SF6 emissions is to invest in proper training and equipment. Ensuring that employees handling SF6 are properly trained is a crucial piece in the proper operation of SF6 gas handling equipment. DILO provides great SF6 Safety & Handling training ) that is offered in both the virtual and in-person format to ensure you can keep your organization up to date on best practices as well as industry regulations. Utilizing zero-emission gas handling equipment such as a room monitor system or the correct size of recovery unit will also help to reduce potential SF6 leaks into the environment.

A second step is the utilization of zero-emission gas handling equipment that is properly sized for the volume of gas you are working with to ensure as low of a blank-off pressure as possible with quick recovery.

A third step in reducing SF6 emissions is to choose to use reconditioned rather than virgin SF6 gas. There is not only a cost savings of using reconditioned gas versus virgin gas, but SF6 that has been reconditioned to DILO’s standards meets or exceeds the IEEE standards and may be used in place of virgin gas.

Lastly, we can reduce potential SF6 leaks by using the correct fittings and adapters. It is important to make sure that all fittings used for GIE connections are leak tested as well as to avoid those with threaded connections. Fittings that have a metal -to-metal connection are ideal when it comes to SF6 handling.

What the Future Holds for SF6 Gas

Given it’s less-than-ideal environmental impacts, the future of SF6 gas use in the electrical industry is likely fleeting. The transition out of using SF6 switchgear will be a slow process as the remaining gear ages and is eventually retired. The utilities considering switching to alternative gases will need to make significant investments to switch out their existing equipment. The current main alternative gases that are making strides in the electrical world are gas mixtures such as C4 and C5 and Synthetic Air Applications.

It should be noted that current available alternative di-electrics cannot be utilized with existing SF6 switchgear. An exciting advancement, however, is Hitachi Energy’s announcement of their EconiQTM, which is the first replacement product for installed or existing gas-insulted switchgear using a gas mixture that is fluoronitrile-based (C4). This new product not only allows for the reduction in environmental impact, but also the cost of switching equipment that would otherwise work for many more years.

If you’re looking to learn more about alternative gases, join us at our upcoming Annual SF6 Gas Seminar. This event includes presentations and we will have two break-out sessions on Alternative Gas Topics. Sign up here!