SF6 Gas Recovery

SF6 Gas Recovery is the term used for removal of SF6 from a Compartment or Gas Insulated Equipment (GIE). This is different from evacuation, which is the function for removal of AIR.

Determining SF6 Gas Volume

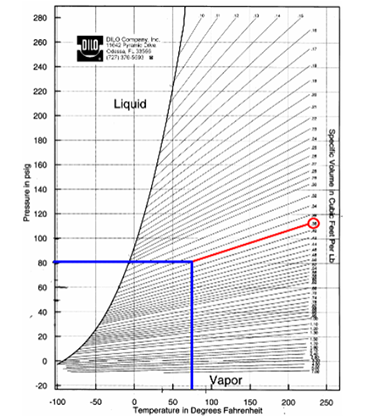

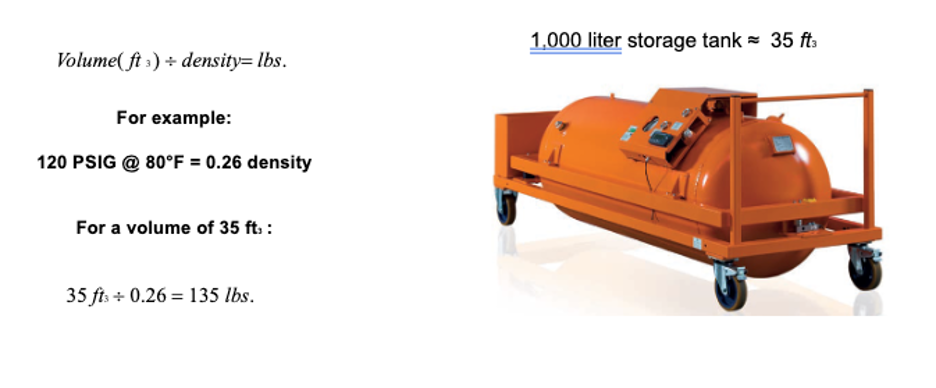

It’s important to understand the volume of SF6 that you’re dealing with prior to beginning SF6 gas recovery. Knowing the volume of SF6 gas that needs to be recovered will help you select the correct tools and avoid emissions. The SF6 Density Curve along with following formula can be used to determine the number of pounds (mass) of SF6 within a given volume:

Volume (ft3) / density = lbs.

You can use a SF6 Density Curve (table 01 below) to determine the density of SF6 using the compartment size and ambient temperature. Then, you can use the density along with the tank volume to determine the pounds of SF6 gas.

The nameplate on a GIE can also be used to determine the amount of SF6 to be recoveredfrom a GIE, but beware of nameplate inaccuracies.

Understanding Residual Gas

Any gas that is not recovered will be left inside the GIE as residual gas and can potentially be emitted into the atmosphere. Residual SF6 in a recovery system, hoses, and other gas handling accessories must also be accounted for. Any number greater than 760 torr/mmHg is a positive pressure and indicates that there is residual gas within the GIE and/or recovery system. Using a mass flow meter during recovery will help determine the actual volume of SF6 gas that has been moved to avoid leaving any residual gas within the GIE or gas handling equipment.

Impact of Blank-Off Pressure on SF6 Recovery

When completing SF6 recovery using a gas cart, it is imperative to reach the lowest level of vacuum possible, or “blank-off pressure.” In the past, a recovery vacuum level (blank-off pressure) of 37.5 Torr/mmHg (50 mbar) was acceptable. This was due to the limitations in vacuum pump technology at the time.

Improvements in recovery system technology, combined with ever increasing regulations, require the SF6 to be recovered to as low of a blank-off pressure as possible. For volumes less than 100 lbs. SF6, a minimum blank-off pressure of < 5 mbar/ 3.75 torr is adequate. For volumes greater than 100 lbs. SF6, a blank-off pressure of < 1 mbar/ 0.75 torr is recommended. At these blank off pressures, virtually all the gas is recovered.

Recovering to 0 PSIG, instead of blank-off pressure, can lead to lot of residual gas left in the GIE. For example, a GIE containing 340 lbs. of SF6 at 90 PSIG that is recovered to 0 PSIG (760 torr) will have 47.74 lbs. of residual gas left in the GIE. This residual gas will be emitted into the atmosphere if that breaker is opened to perform maintenance. This emission has negative consequences for the environment and can also cost your company money in fines depending on local and federal regulations. Recovering the same GIE to blank-off pressure of 5 torr will result in only 0.31 lbs. of residual SF6 gas, a much more favorable outcome.

Using Adequate Recovery System

You wouldn’t want to use a Mini Cooper if you were taking your family of 7 on a cross-country road trip. Could you do it? Technically, yes; but the experience would be much more enjoyable if you selected a minivan instead. Similarly, you need to have the correct recovery system for your particular SF6 gas handling needs. Selecting and utilizing the right tools for SF6 gas handling is half the battle to performing the job efficiently and in an environmentally friendly way.

Below is a list of major criteria to consider when selecting a recovery system:

- Recovery times allowed

- Final vacuum to be achieved

- Volume of the largest gas compartment

- Maximum permissible storage weight

- Cycle times allowed for SF6 Recovery, Filling, and Evacuation of AIR

- Local, State, and Federal Regulations

- Available Budget

For the next few examples, we will pretend that we are attempting to recover 150 lbs. of SF6 gas at 75 PSIG to 3.75 torr using a 15’ hose.

Utilizing an Undersized Recovery System

If we used a B143 Mini Series Gas Cart for this application, recovery to 3.75 torr would take over 15 hours. This is more than a day of work, leading to inefficiency in terms of personnel planning. A Mini Plus is ideal for recovering around 60 lbs. of SF6. Utilizing a system in this manner adds unnecessary wear and tear to the equipment, reducing its lifespan and increasing maintenance intervals for the machine.

Utilizing an Adequate Recovery System

If we used an L057 Economy Series Gas Cart for the same application, recovery to 3.75 torr would take 3 hours. This can easily be completed within one day of work and makes for much more efficient use of personnel time. Additionally, no unnecessary stress is placed on the equipment.

Hose Length: Size Matters

Selecting the correct recovery system is not the only equipment you need to consider when selecting tools for SF6 gas handling. The length of the hose used in SF6 recovery has an impact on recovery time as well, and bigger is not always better. The examples above used a 15-foot hose to recover to 3.75 torr. If you used the L057, the adequate recovery system for this job, but used a 65-foot hose, recovery time jumps from 3 hours to over 6 hours.

DILO Time Calculation App

We have a convenient app that allows you to calculate and compare recovery time and residual gas using different recovery systems with a given volume and desired recovery pressure. This tool also takes hose length into consideration. Ryan Donnelly has a great Pro-Tip on how to use the App and where to find it below:

Recovery Systems Break-Out Session

Would you like more information? If you attended the 2021 SF6 Gas Management Seminar, you can log in and review Robert and Corey’s Break-Out Session “The Recovery Systems Best Suited for Every Application”. Our Annual SF6 Gas Management Seminar is a cost-effective way for your team to learn more about SF6 gas handling Safety and best-practices, straight from industry experts. Each year, we dedicate an entire day of hands-on break-out sessions to gas handling topics. We are so excited to be back in-person in Tampa, Florida on November 8-9. Save even more by taking advantage of the early bird discount registering before August 26!

Please feel free to contact us with any questions.