The Future of SF6 Gas

Alternatives to SF6 gas have made great strides in the last few years. SF6 gas has been the preferred gas in electrical switchgear for over 50 years due to its dielectric strength, arc quenching capability, and thermal stability.

The dielectric strength of SF6 increases with pressure, therefore smaller circuit breakers can be used at higher voltages allowing a reduced overall footprint compared to other insulating mediums. Additionally, sulfur hexafluoride is non-toxic and self-healing gas. It takes an immense amount of heat to break the bonds between the molecules, and once the heat source is removed the atoms will recombine immediately.

Unfortunately, the qualities that make SF6 indestructible in an electrical environment also make it the single most potent greenhouse gas ever measured with a global warming potential (GWP) 24,300 times more effective at trapping infrared radiation than CO2 with over a 100 year lifespan.

While impressive, this measurement is a clear indication that industries like T&D Insustry electronics and manufacturing need safe and effective SF6 gas alternatives to ensure eco-friendly operations with matched efficiency.

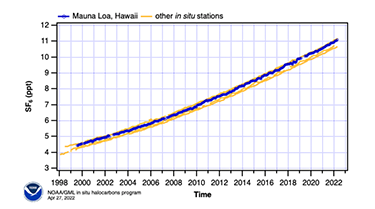

Despite an increase in awareness and implementation of state and federal emission limits and regulations on SF6 gas, the proportion of SF6 in the atmosphere has risen continuously worldwide since the year 2000 (see Figure 1 below).

Figure 1: Proportion of SF6 Gas in the Atmosphere

(Source: https://gml.noaa.gov/hats/insitu/cats/conc.php?site=mlo&gas=sf6)

Figure 1: Proportion of SF6 Gas in the Atmosphere

(Source: https://gml.noaa.gov/hats/insitu/cats/conc.php?site=mlo&gas=sf6)

Technology enhancements have optimized SF6-insulated equipment over the past 30 to 40 years. Advances in technology and years invested in R&D have allowed Original Equipment Manufacturers to start producing GIS switchgear with various alternatives to SF6 Gas.

The move away from SF6 switchgear is inevitable, but it will be a slow process that occurs as existing SF6 switchgear ages out and becomes decommissioned. Utilities looking to make the switch to Alternatives to SF6 gas will have to make large investments to replace existing SF6 switchgear.

It is important to note: alternative dielectrics currently on the market cannot be used with existing SF6 switchgear. Hitachi has announced EconiQ, which is expected to hit the market in late 2022 and is designed to replace SF6 gas in existing equipment. SF6 service carts are not designed to be used with any Alternative Gases

Available Alternative Gasses That Are Making Strides: C4 and CA

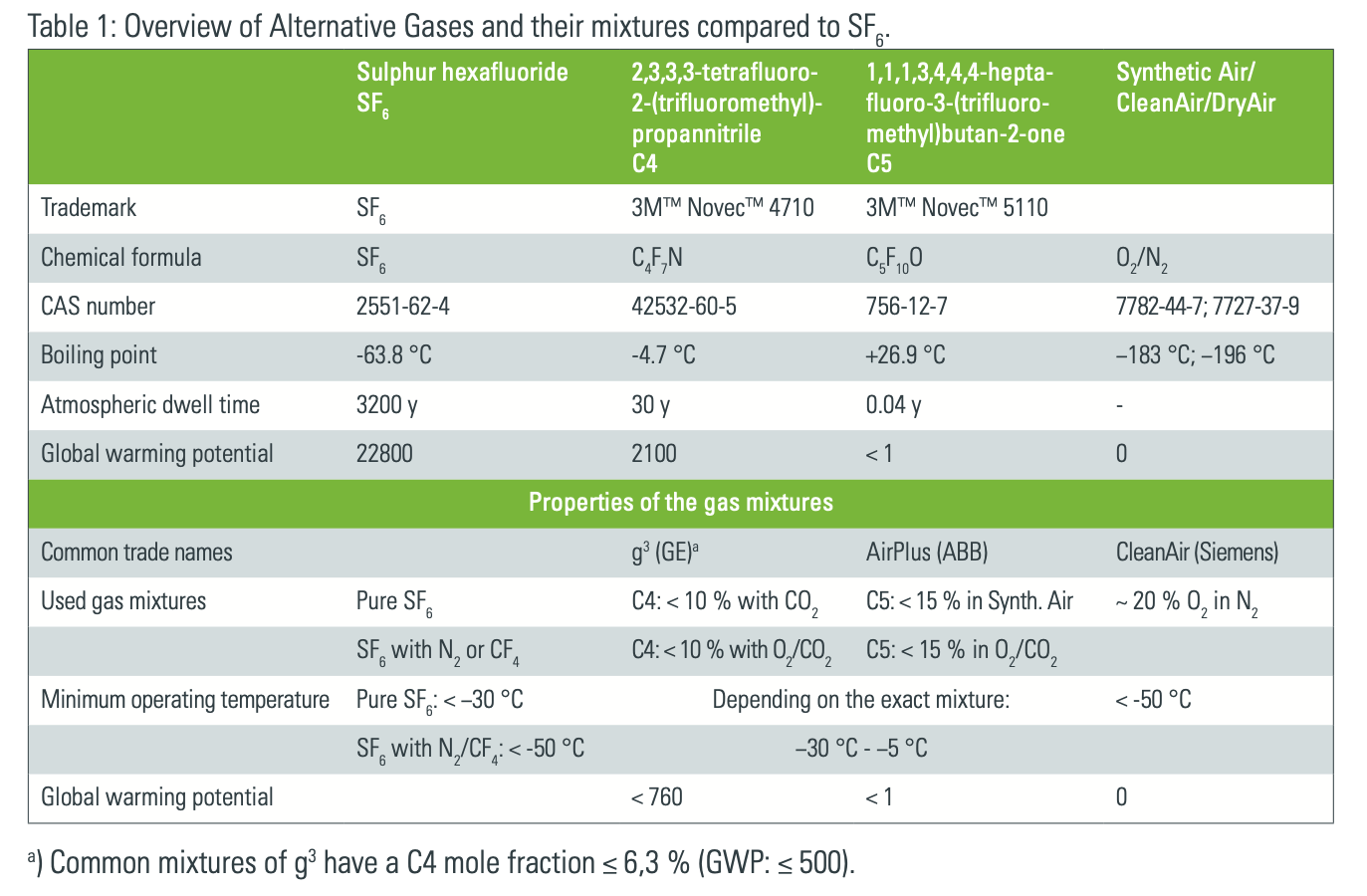

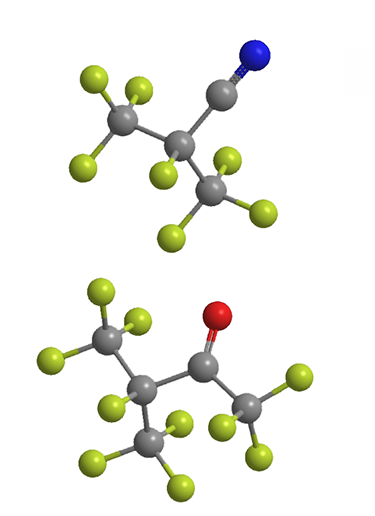

Regarding SF6 gas replacements, two developments stand out with great potential for an efficient upgrade. These are C4 and CA. C4 is Fluoronitrate, another fluoride gas with similar properties, but far lower greenhouse impact. CA stands for Clean Air, also known as Dry Air, Synthetic Air, or Technical Air systems.

SF6 alternative gasses consist of gas mixtures of two or more single gas components that form the insulating medium. This is in contrast to SF6 gas which consists of a single component.

SF6 alternatives meet the requirement of having considerably lower GWP and a shorter atmospheric lifespan to ensure that small leaks in the manufacturing process are less harmful to the environment.

(Source: “Alternative Gases” and Gas Mixtures: Part 1 | DILO White Paper)

(Source: “Alternative Gases” and Gas Mixtures: Part 1 | DILO White Paper)

A Look at the C4 Gas Mixture

C4 (or C4-FN) is a synthetic molecule that, when mixed with oxygen and carbon dioxide or nitrogen, performs similarly to SF6. As an alternative for SF6, C4 in its pure form maintains a liquid state at pressures above 250 kPa.

This stands in contrast to SF6 which maintains a homogenous gaseous state in ambient atmospheric conditions (>-50 °C; <20barabs) with no partial liquefaction. C4 must be mixed with nitrogen or carbon dioxide to mimic the effects of SF6, as these gases require higher temperatures and pressures for liquefaction.

Blending C4 with a carrier gas provides more stability in ambient conditions, but partial liquefaction may occur in extremely cold temperatures. Extreme conditions should be considered when deciding the right mixing ratio and insulating capacity of the gas.

When properly blended, C4 represents an effective SF6 alternative solution because it has the same compact design as SF6 switchgear and the same electrical ratings as SF6 gas. C4 is also able to operate within the same temperature range as SF6, down to -30°C.

In terms of safety and stability, C4 has no voltage limitations and the homogeneity and composition of the gas remains stable over time.

(Source: “Alternative Gases” and Gas Mixtures: Part 1 | DILO White Paper)

(Source: “Alternative Gases” and Gas Mixtures: Part 1 | DILO White Paper)

Exploring CA: Clean Air or Synthetic Air Applications

The second SF6 gas alternative is CA, also known as Clean Air and the more precise application of Synthetic Air using a similar approach.

Clean Air - CA

CA or Clean Air uses purified air as an insulating gas. Natural air is made up of a combination of oxygen, nitrogen, and carbon dioxide, representig a stable blend that is often used in the production of C4 and similar insulating gas alternatives.

Clean air systems are typically hermetically sealed and take up more space than SF6 systems, but the gas can function at extreme temperatures down to -50°C and is completely harmless if the system allows any gas to escape.

Synthetic Air

Synthetic air systems, advance the clean air theory by using a precise mixture of oxygen and nitrogen. They are primarily used in vacuum switching technology up to and below 145 kV.

Vacuum switching has existed for decades, and recent advances have reduced its footprint to rival the compact design of SF6 breakers. Thus, synthetic air is a competitive and safe SF6 gas alternative.

Synthetic air is even more robust than clean air, capable of remaining in a stable gaseous state at -183 °C. It also stays in a homogenous state at room temperature under high pressure. And due to it's simple composition of oxygen and nitrogen, synthetic air is also completely non-toxic and environmentally safe should a leak occur.

Summary of the Leading Alternatives to SF6 Gas

Due to the high GWP impact, it has become imperative to identify and implement safe alternatives to SF6 gas. The leading options today are C4 gas mixtures and CA / Synthetic Air for insulation and electronic environment instead.

Advancing technology enhances our ability to create compact systems that rival the size of efficient SF6 systems to ensure smoother replacements and the ability to maintain internal efficiency without the high risk of environmental harm should the insulating gas escape.

Upgrading SF6 systems promises to be interesting as we see developments in the market for higher voltage switchgear over the next few years.

Looking to Learn More About SF6 and Alternative Gases?

Join us at our Insulating Gas Management Seminar (IGMS) at the Sheraton Sand Key Resort in Clearwater, FL, on February 25-26, 2026. Part of talking about all things SF6 is helping utilities and gas users learn about new alternatives to SF6 technologies on the market.

This year, we will be featuring important subjects including regulation changes at federal and state levels, developments in alternatives to SF6 gas, SF6 gas handling best-practices, emission-free gas handling, and safety precautions.

The Alternatives to SF6: Technological Advances Break-Out Session will cover the latest advancements and developments in emerging and existing alternatives to SF6 gas. Participants will have the opportunity to enjoy a variety of presentations in an intimate group setting.

Register today to save your spot!