High-voltage switchgear, created in the early 20th century, is essential for controlling electricity by switching various elements on and off, ensuring safety in electrical power plants.

This technology is vital for the reliable operation and protection of electrical systems, playing a pivotal role in nearly any electricity use. Developing and implementing high-voltage switchgear has been crucial in advancing the electrical industry, allowing for more efficient and safer management of high-power electrical currents.

Understanding High-Voltage Switchgear

High-voltage switchgear plays a key role in keeping nearly every aspect of power systems under control, which is essential for maximizing their performance and keeping them as safe as possible.

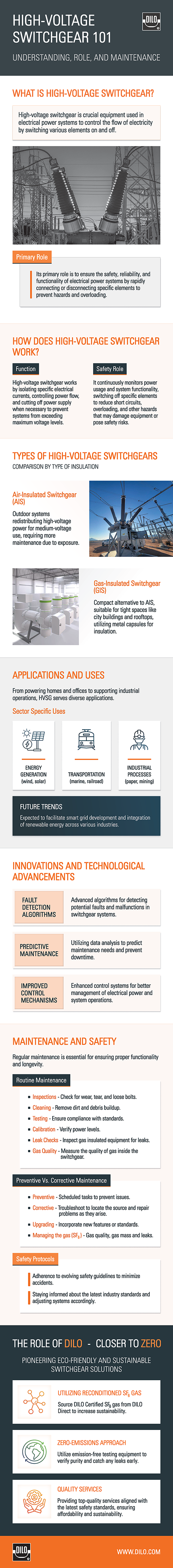

What is High-Voltage Switchgear, and What Is Its Role in Electricity Production?

High-voltage power systems turn electricity on and off to ensure its safety and functionality. They are crucial in keeping modern societies up and running, but even minor malfunctions can quickly cause widespread inconvenience and significant safety hazards. High-voltage switchgear aims to mitigate these problems by rapidly connecting or disconnecting specific elements of larger systems to make electricity use as safe and reliable as possible.

This type of switchgear is used as a control system capable of quickly turning off all or part of a high-voltage power system to reduce the impact of a safety concern that results from a malfunctioning system or make safely working on a system possible. It can also make it easier to get systems back up and running following a power outage.

How Does High-Voltage Switchgear Work?

High-voltage switchgear works by isolating specific electrical currents, controlling the amount of power that flows through them, and cutting off their power supply when necessary to ensure that systems do not exceed the maximum voltage levels they were designed for. By continuously monitoring the amount of power each aspect of a more extensive system uses and whether they are functioning correctly, high-voltage switchgear can switch specific elements off to reduce short circuits, overloading, and similar concerns that may damage equipment or present a safety hazard.

Critical Components of High-Voltage Switchgear

Understanding how various components of high-voltage switchgear work together is critical to ensuring that they are correctly controlling high-voltage systems and keeping their power at reasonable levels, as well as quickly locating, isolating, and fixing problems if switchgear malfunctions. Some of the most essential parts of a high-voltage switchgear system include:

- Circuit breakers, which are used to connect, carry, and disconnect currents to keep power systems at a reasonable level and automatically prevent them from exceeding the power system's maximum voltage

- Instrument transformers, which are used to transform or isolate specific voltage levels

- Earthing switches which are used to close circuits when no current is present to improve the safety of high-voltage switchgear when it is not being used

Types of High-Voltage Switchgear

Several types of high-voltage switchgear are available, and choosing the most appropriate option for your situation is an important step in ensuring functional and safe operation.

Comparisons Between High-Voltage, Medium-Voltage, and Low-Voltage Switchgear

Most modern electrical grids utilize high-voltage switchgear, designed to replace earlier medium-voltage systems that were much less capable of providing electricity that meets modern standards. Equipment classified as high-voltage generally uses alternating currents with 1,000 V or more or direct currents with 1,500 V or more.

While high-voltage systems are the most common, medium-voltage and low-voltage systems can still be used to run lower-power items that do not need or cannot be exposed to higher voltages. These systems are classified based on their total voltage ratings, which include:

- 36kV or above (HV)

- 1-36kV (MV)

- 1kV or below (LV)

High-Voltage Air-Insulated Switchgear

High-voltage air-insulated switchgear, also known as AIS, is a complex system that redistributes high-voltage power to be used for medium-voltage purposes. These large systems can only be used outdoors, so choosing this option will likely result in more maintenance needs.

High-Voltage Gas-insulated switchgear

High-voltage gas-insulated switchgear, also known as GIS, is a more compact alternative to high-voltage air-insulated switchgear and more suitable for protecting switchgear in smaller spaces. This type of high-voltage switchgear uses metal capsules to insulate high-voltage switchgear in city buildings, on rooftops, and in other tighter spaces that cannot reasonably accommodate the bulkier equipment associated with high-voltage air-insulated switchgear.

Applications and Uses of High-Voltage Switchgear

High-voltage switchgear has many applications, from primary residential or commercial use to much more complex systems that keep the most power-reliant industries functioning efficiently and safely.

Sector-Specific Uses

In addition to providing general electricity to the majority of society, high-voltage switchgear can support and advance various industries' capabilities. Some of the most common areas in this type of switchgear play a crucial role in advancing include:

- Wind turbines, generators, solar power, and other aspects of the energy industry

- Paper, mining, steel, and other industrial uses

- Marine, railroad, and other transportation uses

- Data Centers

Future Trends and Emerging Applications

High-voltage switchgear has already played a major role in transforming how electricity can safely enhance nearly any industry, and it also has the potential to continue to lead to significant advances in the capabilities of various industries. For example, this type of switchgear is predicted to play a vital role in advancing the use of smart grids and renewable energy integration across various industries.

Innovations and Technological Advancements in High-Voltage Switchgear

Switchgear technology is constantly evolving, and some of the most significant advancements in the safety and capabilities of switchgear include:

- Fault detection algorithms

- Predictive maintenance capabilities

- Improved control mechanisms

How DILO Is Pioneering Eco-Friendly and Sustainable Switchgear Serivice Solutions

At DILO Direct, we prioritize safety and quality in everything we do. Our zero-emissions approach to switchgear gas management gives us a distinct advantage over many competitors. We also utilize Reconditioned SF6 gas to insulate high-voltage switchgear, which can be reused to mitigate the effects of the emissions that most power plants create.

Maintenance and Safety of High-Voltage Switchgear

Regular maintenance can reduce the number of repairs that may need to be made, and locating and fixing any problems that do impact your switchgear system as early as possible can improve its lifespan by preventing more significant problems.

Routine Maintenance Requirements

Maintaining high-voltage switchgear regularly is an important step in ensuring that it can function as effectively as possible because switchgear in poor condition may be unable to properly turn systems on and off when a situation requires it arises. Some of the most important switchgear routine maintenance requirementsinclude:

- Frequent inspections to look for loose bolts or other signs of general wear and tear

- Cleaning switchgear to reduce potential problems associated with dirt and debris buildup

- Testing switchgear systems to ensure that they meet current standards and making any needed changes

- Calibrating switchgear to ensure that power levels are functioning according to current settings

- Inspect gas insulated equipment for leaks

- Measure the quality of gas inside the switchgear

Preventive vs. Corrective Maintenance Strategies

Many potential high-voltage switchgear problems can be prevented through regular preventative maintenance. However, your team may still need to make occasional repairs to respond to the issues that are interfering with the functionality of your switchgear. Some of the main corrective maintenance strategies your team may need to implement include:

- Troubleshooting to locate the specific source of a problem

- Repairing malfunctioning parts or replacing them if they are too badly damaged to be repaired

- Upgrading certain aspects of your switchgear to incorporate new features or better align with newer safety standards

- Managing the gas (SF6) - gas quality, gas mass, and leaks

Safety Protocols and Industry Standards

Like many industries, high-voltage switchgear safety standards are constantly evolving. This means that staying on top of the latest safety guidelines and adjusting your current system to meet them is a must to reduce the possibility of accidents, avoid potential fines, and otherwise keep your switchgear up to minimum standards.

For example, breakers filled with SF6 or C4 gas must be checked for gas quality before handling. This is where DILO comes in. We offer maintenance equipment and on-site field services for both types of insulating gas. Additionally, if SO2 gas is detected, additional safety steps are needed. These are just some of the gas-handling recommendations for SF6 circuit breakers.

Choose DILO for Superior SF6 Gas Handling Services

At DILO, we specialize in SF6 gas handling, an essential component used in high-voltage switchgear. Our expertise in SF6 handling is a major advantage in ensuring that these switchgear systems operate at their best and have an extended lifespan. We are committed to providing top-quality services that meet the latest safety standards, ensuring affordability and sustainability. Our dedication to zero emissions technology aligns with your eco-friendly goals, which is why we offer training for breaker maintenance and onsite gas-handling services. Contact us today to discover how our SF6 handling services can enhance the performance and longevity of your high-voltage switchgear.