Addressing Arc Fault Risks in High-Voltage Installations

In high-voltage electrical infrastructure, arc faults are one of the most dangerous and disruptive hazards operators face. These electrical faults, characterized by an unintended electrical discharge between conductors, can endanger lives, disrupt operations, and incur massive financial costs.

For safety officers, electrical engineers, and procurement teams, understanding and mitigating the risks of arc faults is not only a technical challenge but a regulatory and operational imperative.

Thanks to advancements like SF₆-insulated switchgear and sophisticated gas-handling systems provided by companies like DILO, it’s now possible to dramatically reduce arc fault risks while improving system reliability and safety compliance.

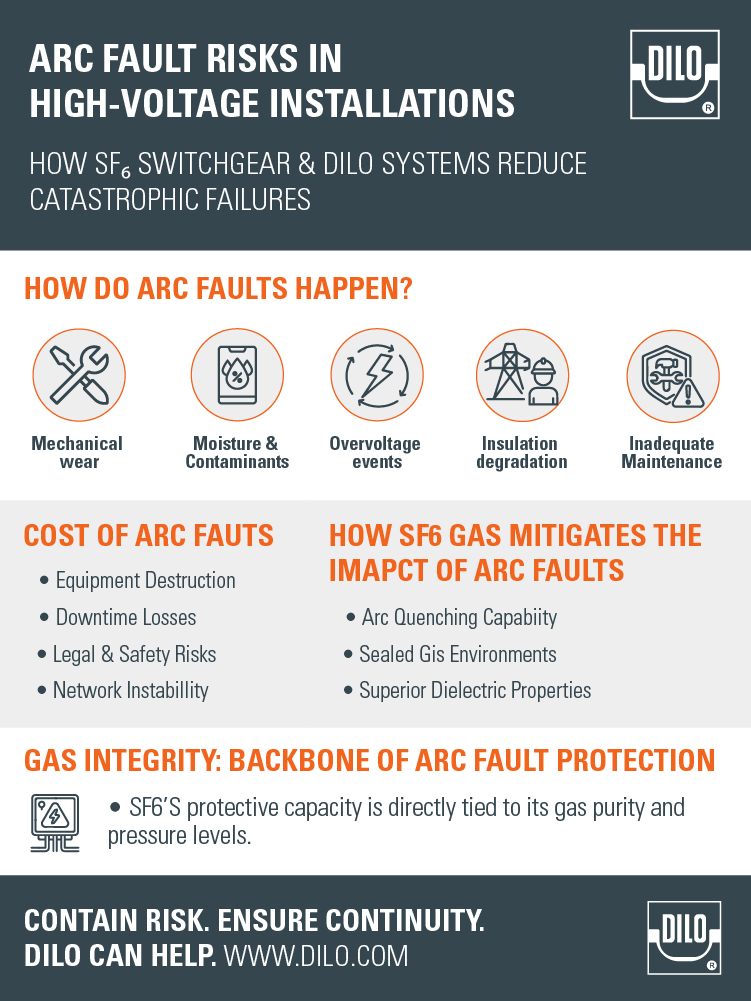

What Causes Arc Faults in High-Voltage Installations?

An arc fault is a specific type of electrical fault where current jumps across an air gap between conductive parts, creating a high-temperature plasma arc. Unlike arc flash events, which involve broader surface discharges, arc faults often occur within equipment enclosures, making them harder to detect and potentially more destructive if left unchecked.

But how does an arc fault occur? Multiple contributing factors can trigger these dangerous discharges:

- Insulation degradation: Over time, insulation materials in high-voltage equipment break down due to thermal stress, UV exposure, and aging. Even minor cracks or voids can create pathways for arcing.

- Mechanical wear and tear: Switchgear connectors, busbars, and contact assemblies can develop loose connections or misalignments due to repeated operation cycles or vibration, increasing fault susceptibility.

- Contamination and moisture: In gas-insulated switchgear (GIS) systems, moisture ingress or particulate contamination compromises dielectric integrity, raising the risk of arc faults during overvoltage events.

- Overvoltage incidents: Lightning strikes, switching surges, or grid instabilities can create voltage spikes that overwhelm even robust insulation barriers.

- Inadequate maintenance: Improper maintenance protocols, skipped inspections, or incorrect torque settings on bolted connections leave systems vulnerable.

In other words, arc fault risks are a product of both aging infrastructure and operational oversights and they can arise even in regularly maintained systems.

The Human, Systemic, and Financial Cost of Arc Faults

The consequences of an arc fault extend far beyond equipment failure. They constitute an occupational hazard with potentially tragic outcomes. According to OSHA electrical standards, arc faults and related incidents are responsible for hundreds of worker injuries and fatalities annually. Temperatures within an arc can exceed 35,000°F, instantly vaporizing metals and creating explosive pressure waves.

From a systemic perspective, arc faults can lead to:

- Severe equipment damage: Destroyed switchgear, transformers, and control systems may take months to replace.

- Extended unplanned downtime: Utility companies and industrial facilities can lose millions due to outages and production halts.

- Cascading failures: In high-voltage installations, a localized arc fault can ripple through the network, causing widespread service disruptions.

- Regulatory penalties: Non-compliance with safety frameworks such as IEC 62271 standard and OSHA electrical standards exposes operators to fines and legal action.

And no, arc faults do not always result in explosions. However, when confined gases ignite or structural failures occur, the consequences can be catastrophic.

How SF₆ Gas Mitigates the Impact of Arc Faults

One of the most effective strategies to address arc faults involves using SF₆-insulated switchgear. Sulfur hexafluoride (SF₆) is an electronegative gas known for its exceptional dielectric strength and arc-quenching properties. Unlike traditional air-insulated switchgear, SF₆ systems isolate high-voltage components inside sealed chambers filled with the gas, drastically reducing fault occurrence and severity.

Here’s why SF₆ excels:

- Superior dielectric properties: SF₆ can withstand higher voltages before breakdown occurs, limiting the formation of arcs even under stress conditions.

- Arc quenching capability: If an arc initiates, SF₆ quickly absorbs free electrons, suppressing the arc within milliseconds and minimizing thermal damage.

- Sealed GIS environments: Isolating components from air, dust, and moisture, SF₆-insulated GIS systems prevent many of the contamination issues that plague open-air systems.

In simple terms, SF₆ doesn’t prevent arcs from starting entirely but stops them from escalating into destructive events, offering a significant edge over open, air-insulated systems.

You can explore DILO’s complete line of SF6 products designed for gas handling, testing, and analysis across various high-voltage systems.

Gas Integrity: The Backbone of Arc Fault Protection

While SF₆ offers outstanding arc mitigation, its protective capacity is directly tied to its gas purity and pressure levels. Even small leaks or contaminants can reduce dielectric strength, making real-time monitoring essential.

Why monitor SF₆ gas in real-time? Because gas deterioration can happen quietly, long before any visual or operational warning signs appear. Key monitoring practices include:

- Pressure and temperature tracking: Fluctuations may signal leaks or equipment malfunctions.

- Moisture and dew point analysis: Water vapor dramatically lowers SF₆'s insulating capacity.

- Leak detection: Early identification of leaks prevents extensive system contamination and allows for timely corrective action.

Supporting Arc Fault Prevention Through Advanced Gas Handling

Besides monitoring, proper gas handling is equally essential. DILO’s gas-handling systems offer comprehensive solutions that help facilities maintain long-term SF₆ gas integrity:

- Gas leak detectors: Pinpoint even micro-level leaks, ensuring no compromise to insulation.

- Gas analyzers: Knowing the quality of the insulating gas is imperative prior to beginning any gas handling.

- Recovery systems: Allow contaminated gas to be purified and reused, minimizing environmental impact.

- Gas handling services: From inventory tracking to cylinder consolidation and annual reporting, In-Gas Direct—the exclusive gas handling service partner of DILO—has you covered.

Staying Compliant: Arc Fault Safety Under Global Standards

Global safety regulations demand robust arc fault prevention protocols and compliance is non-negotiable. The IEC 62271 standard lays out comprehensive requirements for switchgear design, arc withstand capabilities, and testing methodologies.

In North America, NFPA 70E, OSHA electrical standards, and the National Electrical Safety Code (NESC) impose additional obligations on employers to protect workers and maintain safe equipment. SF₆’s environmental considerations also require operators to minimize emissions and monitor usage to support sustainability goals.

DILO and In-Gas Direct can help organizations achieve net-zero SF₆ emissions through:

- Gas lifecycle management

- Zero-emission recovery units

- Precise gas quality analytics

In this way, DILO doesn’t just support fault protection but it aligns electrical safety with modern sustainability mandates.

Containing Risk. Ensuring Continuity.

Arc faults remain a persistent threat to high-voltage installations, but with the right systems in place, their risks are fully manageable. SF₆-insulated switchgear offers unmatched arc containment, while advanced gas handling and monitoring, like those provided by DILO, ensure that these systems continue performing at peak safety levels for years to come.

Contact In-Gas Direct today to schedule a consultation and take the first step toward safer, more reliable, and fully compliant operations.