There have been drastic changes in the Electrical Transmission and Distribution Industry in the last decade. The environmental impacts of SF6 have led to the increase of other insulating gases being used more broadly. State and Federal regulations and oversight of SF6 gas handling has increased. And finally, the industry is learning to decrease emissions by using best practices in handling insulating gases. It’s an exciting yet overwhelming time!

This year, on January 1, the updates to the US EPA subpart DD of the Greenhouse Gas Reporting Program (GHGRP) (40 CFR 98.300-98.308) took effect. There are some significant changes. In this blog post, you will learn who needs to report, what gases are included, and what the threshold calculation is, and how to use it. We will also cover how to navigate making changes to nameplate capacity.

But first, a little disclaimer. We do not speak for or represent the EPA in any way. This blog post is for informational purposes only and does not provide any legal advice. Ok, let’s get to it!

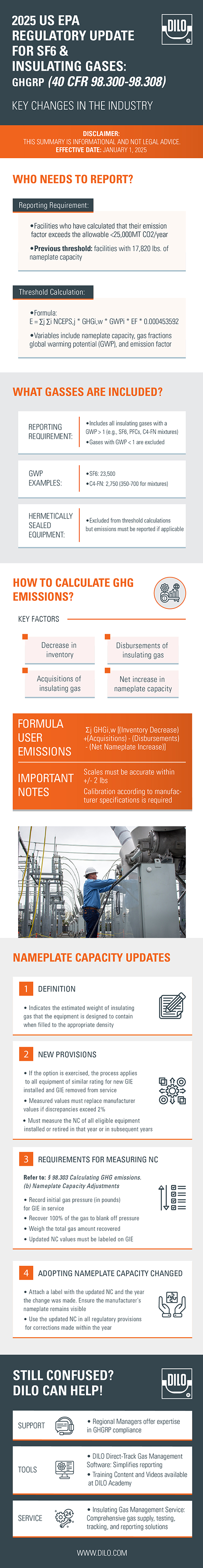

Who Needs to Report?

Effective on Jan 1, 2025, users with total annual greenhouse gas emissions of 25,000 metric tons of CO2e per year, based on the sum calculation for each of SF6 and perfluorocarbons (PFCs), will have to report to the EPA.1 This is a change from the previous requirement, where facilities had to report if they had a total nameplate capacity of 17,820 lbs. or more. In order to determine their annual emission rate, facilities will have to use the threshold calculation.

Threshold Calculation

Whether or not a facility has to report is determined using the threshold calculation. This formula includes the total nameplate capacity of equipment that contains reportable insulating gases, the weight fraction of each fluorinated greenhouse gas (GHG) present in the insulating gas, the Global Warming Potential (GWP), and an assumed emission factor of 10%.1

The formula for calculating annual emissions for threshold applicability is as follows:

E = ∑j ∑i NCEPS,j ∗ GHGi,w ∗ GWPi ∗ EF ∗ 0.000453592

Where: E = Annual emissions for threshold applicability (measured in metric tons of CO2 equivalent).

NCEPS,j = Total nameplate capacity of equipment with reportable insulating gas j (excluding hermetically sealed-pressure equipment) within the facility, plus the total nameplate capacity of gas insulated equioment not located on-site but under common ownership or control (in pounds).

GHGi,w = Weight fraction of fluorinated GHG i in the reportable insulating gas j within the gas-insulated equipment included in the total nameplate capacity

NCother,j, expressed as a decimal. If fluorinated GHG i is not part of a gas mixture, a value of 1.0 should be used.

GWPi = The GWP specific to the gas, as listed in Table A-1 of subpart A.

EF = Emission factor for electrical transmission and distribution equipment (in pounds emitted per pound of nameplate capacity). For all gases, an emission factor of 0.1 should be applied.

What Gases are Included?

Reporting is no longer limited to SF6 gas. As of 2025, all insulating gases with a global warming potential (GWP) of greater than one must be included in the total nameplate capacity threshold calculations2. Global warming potential is a measure of how much a certain greenhouse gas contributes to global warming when compared to carbon dioxide. Facilities are not required to report the emissions of insulating gases with a GWP of less than one2.

The EPA defines an insulating gas as any fluorinated greenhouse gas (GHG) or mixture of fluorinated GHGs, which encompasses but is not limited to SF6 and perfluorocarbons (PFCs), utilized as an insulating and/or arc-extinguishing gas in electrical apparatus.

Carbon dioxide has a GWP of 1 and SF6 has a GWP of 23,500. The GWP for C4-FN is 2,750 and the GWP for C4-FN mixtures varies from 350-7003. This means SF6 and C4-FN mixtures must be included in a facilities threshold calculation. A list of gases and their GWP can be found on “Table A-1 to Subpart A of Part 98—Global Warming Potentials, 100-Year Time Horizon” on the Code of Federal Regulations Website.

Insulating fluids in hermetically sealed equipment are not included in the threshold calculation, but any emissions that occur from hermetically sealed equipment would need to be reported if the facility is required to report.

For subpart SS, only the reportable insulating gases are considered in threshold calculations and are included in the total emissions figures. Nevertheless, specific amounts of other insulating gases must also be reported. This includes the quantities supplied to customers in new equipment, those charged into equipment at customer locations, and those provided in containers. Additionally, the nameplate capacities of the equipment that contains these other insulating gases must be reported.1

How do I calculate GHG Emissions?

The annual emissions of each fluorinated greenhouse gas with a GWP of greater than one must be calculated and recorded using a mass balance equation.

Before we dive into the math, let’s make sure we understand the terms included in the equation. The EPA defines user emissions as emissions of fluorinated greenhouse gases from the facility in pounds. 2

The Decrease in Inventory of Reportable Insulating Gas is the difference between any reportable insulating gas stored in containers or cylinders at the beginning of the year to that in those containers at the end of the year. This does not include any gas in energized equipment. 2

Acquisitions of Reportable Insulating Gas is the sum of any reportable gas in pounds that has been purchased or acquired (including gas that was shipped with or inside of equipment, both in use and not in use) and the pounds of SF6 gas returned to a facility after off-site recycling. 2

Disbursements of Reportable Insulating Gas is the sum (in pounds) of reportable gases that have been returned to suppliers, sent for off-site recycling, sent for off-site destruction, and that sold/transferred on its own or inside of any equipment that was in use or not in use. 2

Net Increase in Total Nameplate Capacity of Equipment Operated Containing Reportable Insulating Gasis the difference between the nameplate capacity of new equipment and retiring equipment. Remember, nameplate capacity is defined as the total and intended gas charge within equipment, as outlined by the manufacturer, in contrast to the actual charge, which may be lower due to potential leaks. 2

Now that the terms are clear, it’s time for the math. Below is Equation 4 under subpart DD of the Greenhouse Gas Reporting Program (GHGRP) (40 CFR 98.300-98.308):2

User Emissionsi = Σj GHGi,w * [(Decrease in Inventory of Reportable Insulating Gas j) + (Acquisitions of Reportable Insulating Gas j) – (Disbursements of Reportable Insulating Gas j) – (Net Increase in Total Nameplate Capacity of Equipment Operated Containing Reportable Insulating Gas j)]

GHGi,w The weight fraction of fluorinated GHG i in reportable insulating gas j if reportable insulating gas j is a gas mixture, expressed as a decimal fraction. If fluorinated GHG i is not part of a gas mixture, use a value of 1.0.

It’s important to note that scales used to weigh the gases must be accurate to within +/- 2 lbs. of true weight and the scales must be calibrated according to manufacturer specifications. 2

Nameplate Capacity

The nameplate capacity for each piece of equipment is defined by the equipment manufacturer and indicates the estimated weight of insulating gas that the equipment is designed to contain when filled to the appropriate density. It is important to note that the nameplate capacity does not reflect the actual quantity of gas present in the equipment.

You can read more about nameplate verification and it’s importance at this blog post. The short summary is that nameplate values provided by equipment manufacturers are not aways accurate and these discrepancies can lead to an underestimation or overestimation of emissions.

With the 2025 update, subpart DD includes an optional provision for facilities to measure and correct nameplate values on closed-pressure electrical equipment with a voltage capacity of more than 38 kV.

Measurement is optional; however, if a facility chooses to measure the nameplate capacity (NC) of any equipment, it is required to measure the NC of all eligible equipment that was either installed or retired during that year or in subsequent years.

If the facility's measured NC differs from the manufacturer-specified NC by more than two percent, the facility must use the measured value. Conversely, if the facility's measured NC is within two percent of the manufacturer-specified NC, it is not obligated to adopt the measured value. Nevertheless, if the facility decides to adopt the measured value, it must apply this to all facility-measured NCs that fall within two percent of the manufacturer-specified value.

It’s all or nothing for nameplate value changes. This prevents the cherry-picking of which nameplate values to correct, which could artificially decrease a facility’s emission rate.

Requirements for Measuring Nameplate Capacity

There are now specific procedures and requirements for measuring the nameplate capacity of New and Retiring gas insulated equipment (GIE) in Subpart DD.1 The process below is for determining the NC of New GIE:

- First, the facility must record how many pounds of gas was in the equipment when it was purchased.

- Next, add insulating gas to the equipment to achieve the temperature-compensated design operating pressure as specified by the manufacturer. Implement the manufacturer's recommended procedure to ensure that the measured temperature correctly indicates the temperature of the insulating gas.

- The next step is to measure and calculate the total amount of gas that was added to the GIE. This can be achieved by using a flowmeter or by recording the weight of a gas container before and after filling. Remember to account for any gas left behind in hoses!

- Finally, add the initial amount of gas contained in the GIE from step 1 to the amount of gas added to the GIE in step 2. Congratulations, you have now calculated the nameplate capacity.

Please refer to the EPA’s PowerPoint from the webinar on October 22, 2024 for detailed information on measuring the nameplate capacity of retiring GIE.

Applying Nameplate Capacity Changes

Remember that if you are implementing the NC change for one piece of GIE, you will have to do so for all facility-measured NCs that fall outside of two percent of the manufacturer-specified value.

Below are the requirements set forth by subpart DD for adopting nameplate capacity (NC) changes:

- In the event that the electrical equipment, for which the NC was assessed, remains in use, the facility is required to attach a label to the equipment indicating the updated NC value along with the year in which the NC adjustment was conducted. It is essential that the manufacturer's original NC label remains clearly visible.

- For GIE that undergoes an NC adjustment within the reporting year, the updated NC value must be utilized in all regulatory provisions where the NC is mandated to be documented, reported, or incorporated into calculations.

- Facilities are permitted to measure and modify the NC value of any specific piece of equipment only once, unless there is a reasonable expectation that the NC has changed due to modifications to the equipment, such as the replacement of bushings.

Still Confused? DILO and DILO Direct can help!

We hope that we've provided valuable insights into the recent updates to the US EPA subpart DD of the Greenhouse Gas Reporting Program (GHGRP) (40 CFR 98.300-98.308). However, if you have any questions, we are here to assist you. Our DILO Regional Managers are specialists in this area and are eager to delve deeper into any specific topics you may want to discuss.

Moreover, DILO Direct offers a variety of tools designed to simplify the reporting process. We can assist with every aspect of reporting, from measuring and correcting nameplate capacity to managing the reporting through our DILO Direct-Track Gas Management Software. If you prefer, we can take over the entire gas management process with our Insulating Gas Management Service, which includes everything from gas supply and SF6 handling field services to gas testing, logistical support, and comprehensive tracking and reporting of SF6 using.

Sources:

- EPA Webinar on 10/22/24 : www.epa.gov/system/files/documents/2024-10/webinar_revisions_dd_ss.pdf

- EPA Fact Sheet : Electric Transmission and Distribution Equipment Use- Subpart DD, Greenhouse Gas Reporting Program. www.epa.gov/system/files/documents/2024-12/dd_electrictransmission_infosheet_2024.pdf