Nameplate Capacity and Nameplate Discrepancies

Nameplate capacity or nameplate value is determined by the manufacturer and specifies the approximate pounds SF6 that the Gas Insulated Equipment should hold when filled to the proper density. As explained below, this value is important because it’s used in the Mass Balance Equation to report end-of-year SF6 emissions data. The nameplate value can be hard to read, so be sure to check out the pro-tip below:

It is important to note that the nameplate value is not the maximum amount of SF6 gas that GIE can hold. Additionally, the density (not mass) of SF6 gas is the most important factor for the GIE to operate as designed including insulation and arc quenching capabilities. Therefore, manufacturers of GIE provide a temperature-pressure curve chart to guide the user on how to properly fill the equipment to the temperature corrected pressure required.

There is no accuracy requirement for the nameplate value, but some manufacturers have started to provide accurate nameplate capacities with new equipment. Original Equipment Manufacturers provide the nameplate value in pounds of SF6 because end-users usually purchase and dispose of the gas in pounds.

Mass Balance Equation

To truly understand negative emissions and phantom emissions, we’ll have to start with a bit of math. The Mass Balance Equation is used to determine leakage rates and emissions from GIE:

User Emissions = (Decrease in SF6 inventory) + (Acquisitions of SF6) – (Disbursements of SF6) – (Net Increase in Total Nameplate Capacity of Equipment Operated).

The “Net Increase in Total Nameplate Capacity of Equipment Operated” is calculated by subtracting the nameplate capacity of retired equipment from the nameplate capacity of the equipment in operation.

Of course, the results from the Mass Balance Equation are only as good as the accuracy of the values used to calculate those results.

Nameplate Discrepancy

A nameplate discrepancy or nameplate inaccuracy occurs when there is a difference between the nameplate value and the pounds of SF6 truly contained in GIE when filled to proper density or temperature corrected pressure. The two main reasons for nameplate discrepancies are design changes in GIE and gas handling errors. Nameplate discrepancies are quite common.

As noted in NEMA’s whitepaper “SF6 Reporting Challenges”:

While current data is somewhat limited, empirical information suggests that a large percentage of GIE currently in service and containing the target density of SF6 contains a different mass of SF6 compared to what is indicated on the nameplate. Data collected by DILO Inc. showed that out of 221 high-voltage circuit breakers—ranging from 34.5 kV to 500 kV—tested over a period of 36 months, only six (6) contained actual SF6 mass that was within 1% of the figure on the nameplate.

Impacts of Nameplate Discrepancies: Phantom Emissions and Negative Emissions

If there is a nameplate discrepancy, users will have inaccurate data when it comes time to report their emissions. This could lead to fines and other penalties for utilities located in states that have enforcement regulations. Nameplate discrepancies could also lead to utilities underestimating their SF6 emissions and environmental impact.

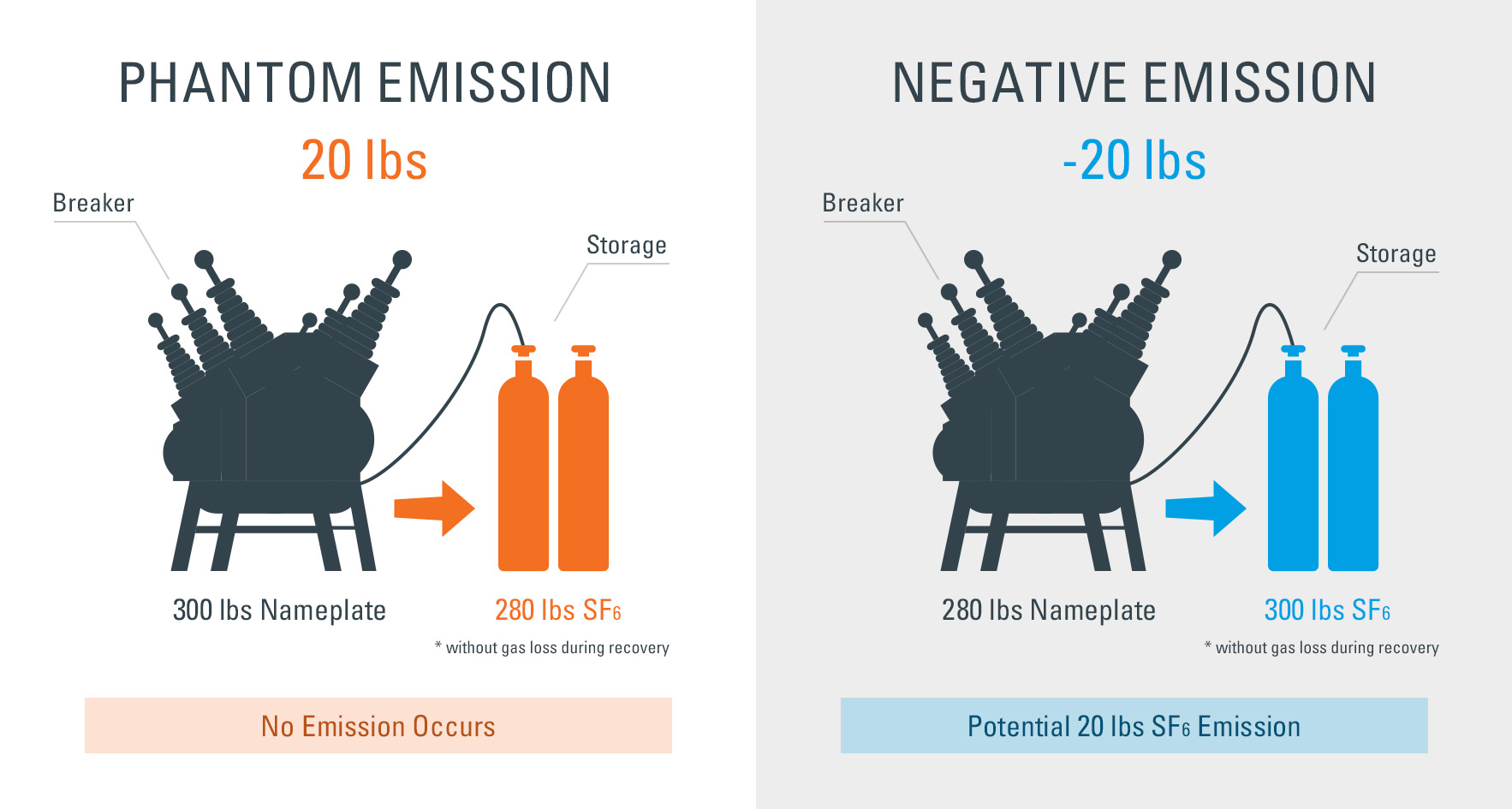

Phantom Emissions

A phantom emission is an emission that did not actually occur. Phantom emissions are the result of a nameplate discrepancy where the capacity of retiring equipment is overestimated. For example, a GIE filled is with 280 lbs. of SF6 in accordance with the OEMs temperature-pressure curve; however, the nameplate value of that breaker is 300 lbs. This would result in a phantom emission of 20 lbs. of SF6. If the end user is required to report SF6 emissions, they will have to report an emission that did not actually occur.

Negative Emissions

Negative emissions are the result of a nameplate discrepancy where the capacity of the retiring equipment is underestimated. For example, a GIE filled is with 300 lbs. of SF6 in accordance with the OEMs temperature-pressure curve; however, the nameplate value of that breaker is 280 lbs. Using the mass balance equation, this would result in an emission of -20 lbs. of SF6. If the end-user is required to report SF6 emissions, they would underestimate their emission rate.

Nameplate Verification

Nameplate verification, the process of determining the exact amount of SF6 in GIE, can help utilities understand exactly how much SF6 they have in their inventory. This can help end-users create a better overview of their SF6 emissions and avoid negative and phantom emissions. The nameplate verification process involves removing all the SF6 in a breaker and precisely weighing the gas via a mass flow meter. It is important that this is performed by a trained technician using state-of-the-art equipment.

State and federal regulations may differ; however, some regulations allow for nameplate corrections in certain instances. These may include the new installation and commissioning of GIE, decommissioning of GIE, or maintenance that may impact the expected nameplate value.

Have questions about any of the above or want to schedule a nameplate verification service with DILO Direct? We are happy to help! Please contact us.