Why is it important that calibration is performed by a professional?

For utilities and manufacturers using SF6 gas equipment, there are two components where calibration is necessary — SF6 gas analyzers and weight scales. Weight scales need calibration once every year, while analyzers require calibration every two years.

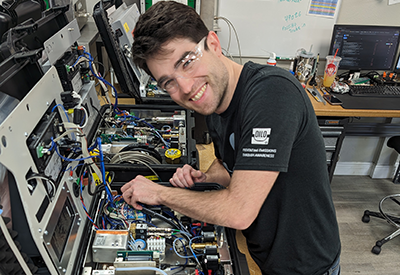

Calibration may seem like a simple enough process. However, you would be remiss not to seek calibration services from a professional. At DILO, we offer SF6 calibration cycles performed by trained calibration specialists. These skilled specialists leverage the proper instruments to conduct the following tasks:

- Bring a device that’s out of tolerance back into tolerance

- Identify abnormalities with your equipment

- Interpret results from units

- Detect false positives

What are the benefits and purposes of calibration?

Regular calibration of SF6 gas analyzers extends the equipment’s service life. It also provides reassurance that the results you receive from the analyzer during testing are reliable.

What’s more, regular calibration can decrease the time and money it takes to service your equipment. At DILO, we’ve found that the analyzers that come in for regular calibration typically require less time for service at the same cost.

Scale calibration is also essential for tracking. When scales are properly calibrated, you receive accurate values when recording the weight of your cylinder before and after filling or emptying.

As mentioned, examining the device is a key aspect of calibration maintenance. Our calibration specialists are sometimes amazed at the strange issues they find with analyzers or weight scales. For example, we’ve received devices with materials or debris from work sites still inside. We’ve also found transport cases with worn-out wheels.

While these problems might not seem as much of a concern as inaccurate results from measuring devices, they reveal another reason why calibration maintenance is so important. Bringing your equipment in provides the chance to detect issues that might otherwise go unnoticed, even if they’re not directly related to the unit’s accuracy.

Services Included in Professional Calibration

At DILO, our process for analyzer calibration begins with a check-in, where the specialist gathers customer data and analyzer information before pushing the device into the line. When the equipment reaches the front of the line, the specialist takes pictures of the current condition and any accessories.

Next, the analyzer is ready for testing. DILO’s calibration service involves the following:

- Assessing for damage and identifying potential repairs

- Checking for retrofits or upgrades that may be necessary

- Checking for leaks

- Evaluating the condition of any accessories

- Updating software

- Testing/calibrating gases and recording results

After these tasks, the calibration specialist will record their findings on a repair sheet. This repair sheet becomes the service report that the customer sees. The customer reviews the report and approves it. From there, the calibration specialist completes the final steps, such as verifying the unit for accuracy.

Improved Accuracy

As with manufacturing applications, the main reason calibration is important with SF6 gas handling is that it ensures accuracy. SF6 gas has excellent electrical insulating properties. Many organizations, from private electrical utility companies to government energy sectors, use it for insulation, arc quenching, semiconductor manufacturing, and more.

At the same time, SF6 gas is a greenhouse gas with a high global warming potential. Users want to ensure they practice emissions-free gas handling to reduce environmental impact.

This is where calibration comes in. It ensures measuring devices like SF6 gas analyzers and weight scales perform optimally. It not only protects against inaccurate readings but can prevent the need for expensive repairs.

Warranty and Certificate of Calibration

When the calibration process is complete at DILO, the specialist sends the unit back to the customer along with a certificate of calibration. Customers receive a certificate for the whole device, not just the sensor.

DILO offers warranties on our calibration services for assurance. If we discover any problems with the services performed on the analyzer within the first 12 months after your service appointment, your warranty provides coverage and peace of mind.*

What are the costs and risks of not calibrating?

Calibration maintenance is an integral part of owning and managing SF6 gas equipment. When units are calibrated regularly, it doesn’t just ensure more accurate test results. Uncalibrated analyzers often deliver longer times, which slows production and can make efforts less profitable.

Calibration also serves as a preventative measure. When a calibration specialist notices a minor issue, they can correct it before it becomes a more significant problem. By waiting, your chance of needing more extensive and expensive repairs increases.

There are risks with not calibrating weight scales as well. Zero emissions are a top priority for any organization handling SF6 gas. A properly calibrated scale helps prevent leaks and the loss of gas from going unnoticed.

Ultimately, when you choose regular calibration maintenance, you reduce costs, streamline operations, and ensure a minimal environmental impact. This allows you to make the most of SF6 gas analyzers and weight scales.

Find Professional Calibration Maintenance at DILO

Ensure the longevity of your SF6 measuring devices by partnering with DILO for SF6 calibration. DILO provides high-quality SF6 products and gas-handling services to help those in the electrical transmission and distribution industry. In addition to our calibration service, we offer gas analyzers, like the Multi-Analyzer SF6, to ensure your organization practices proper gas management. Contact us today to learn more about professional SF6 calibration maintenance.

*additional terms may apply