When winter rolls in, substation maintenance teams feel the pressure before the first snowflake falls. Temperatures drop fast, moisture increases, and gas-filled switchgear experiences real mechanical and dielectric stress. Anyone who was in the industry during the February 2021 cold-weather grid event remembers how quickly failure can cascade. According to the Federal Energy Regulatory Commission’s post-event analysis, equipment breakdowns and unprepared infrastructure contributed to widespread outages. The takeaway is clear: winter readiness cannot wait.

With lessons learned from recent winters and new compliance expectations outlined in NERC EOP-012-2 – Extreme Cold Weather Preparedness & Operations, utilities now recognize that proactive maintenance is not optional. It’s a strategic investment in reliability, uptime, and safety.

This guide is your go-to playbook for winter preparation for SF₆ and alternative insulating-gas fleets. You’ll find an inspection checklist, reliability recommendations, and key performance metrics to track through the coldest months. Plus, there’s a valuable training opportunity coming up in February you’ll want to bookmark.

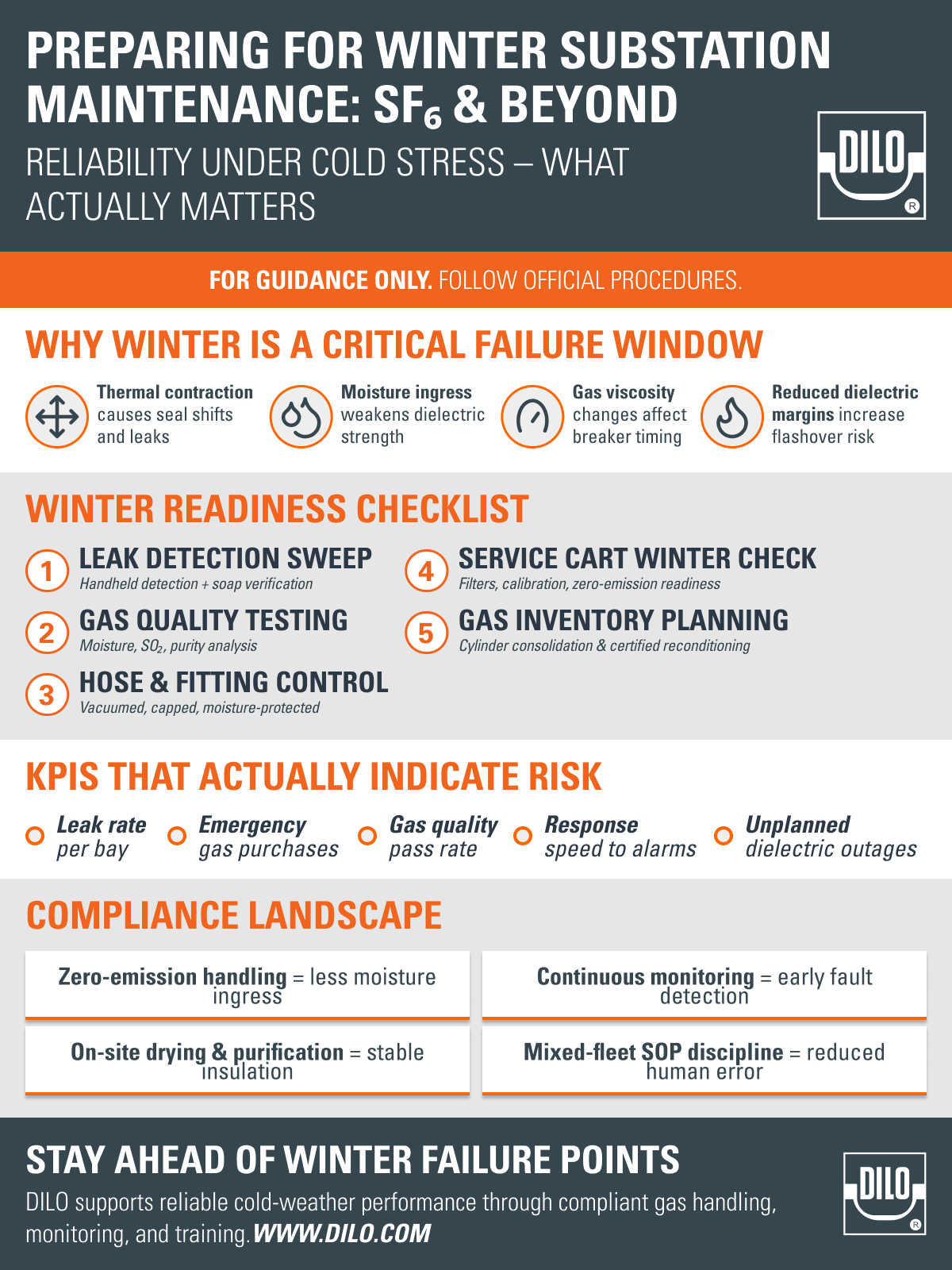

Why Winter Puts Extra Stress on Gas-Filled Assets

Cold temperatures affect gas-filled substation equipment in predictable but critical ways. Thermal contraction causes seals, gaskets, and fittings to tighten and shift, which can lead to small leaks that may go unnoticed until gas density alarms trigger.

Moisture ingress risk increases when hoses aren’t vacuumed or capped correctly, and even trace moisture can rapidly compromise dielectric strength once equipment is under winter load. At the same time, gas viscosity changes can alter how equipment responds during operation and gas handling, slowing transfer rates and affecting breaker timing.

As temperatures drop, dielectric margins tighten, meaning any contamination, moisture, decomposition byproducts, or air has a more severe impact on insulation performance. This is especially true for SF₆ circuit breakers, GIS switchgear, and bays using alternative gas blends. Without proactive maintenance and gas-quality verification, these stress factors can create compounding reliability risks.

Utilities are also facing greater accountability under NERC EOP-012-2, which emphasizes structured winter readiness programs. That translates to clear procedures, trained teams, inspection records, and equipment readiness testing, not reactive troubleshooting mid-storm. The more preparation completed in Q4, the fewer surprises appear in January when grid loading peaks.

SF₆ / Alternative-Gas Inspection Checklist

A focused inspection helps teams prevent most winter-season issues before they start. Below is a streamlined checklist for your maintenance crew. Many teams convert this into a visual one-page field sheet.

Leak Detection Sweep: Perform a thorough inspection of all gas-filled equipment. Use handheld leak-detection devices and confirm findings with a soap-solution test where needed. Consistent sweep routines greatly reduce the need for emergency gas top-offs later.

Gas-Quality Verification: Analyze moisture levels, SO₂ concentrations, and gas purity before load increases and cold-weather transitions. For continuous reliability, consider continuous SF₆ gas-quality monitoring to catch contamination early.

Hose and Fittings Preparation: Vacuum hoses before use, replace aging fittings, and cap everything properly. Frozen ambient air, combined with uncapped fittings, can instantly allow trace amounts of moisture into a system.

Service Cart Readiness: Confirm your gas-handling service carts are winter-ready: filters replaced, oil checked, calibration verified. Zero-emission cart operation helps maintain dielectric strength by minimizing air and moisture ingress, a crucial factor as temperatures drop.

Inventory and Reconditioning Plan: Plan cylinder consolidation and gas reconditioning before emergency conditions hit. Working with a certified supplier keeps gas quality levels consistent and predictable during peak winter demand, especially when coordinating with a DILO Certified Gas partner.

This checklist applies across SF₆ Gas Equipment and fleets transitioning to Alternative Gas Handling Equipment (C4, C5, CF₃I blends, etc.).

How Proper Gas Handling Ensures Reliability in Cold Months

Gas-handling practices directly influence dielectric strength, arc-quenching performance, and equipment longevity. In winter, there’s less margin for error.

- Zero-emission handling prevents moisture and air ingress, protecting the insulating properties of both SF₆ and alternative gas mixtures.

- On-site drying and purification reduce the chances of winter-related flashover.

- Continuous monitoring ensures operators can detect contamination early, before it escalates into a breaker failure or a forced outage.

For mixed fleets, adopting clear alternative-gas SOPs ensures crews can switch between systems confidently without compromising safety.

Learn more about mixed-fleet support and equipment at: Alternative Gas Handling Equipment.

KPIs to Track December–March

Measuring performance during cold months improves long-term fleet resilience. These KPIs help teams understand how well sound equipment is performing at low temperatures and where proactive intervention is needed.

Leak Rate Percentage Per Bay or Fleet Section

Tracking leak rates monthly gives visibility into gradual seal, flange, or O-ring failures that often worsen in freezing conditions. Even minor leaks can escalate under thermal contraction, so trending changes are essential.

Gas-Quality Pass Rate Before Energization and Monthly

Monitoring moisture content, SO₂ levels, and purity stability across the winter season helps maintain strong dielectric strength. If gas quality begins to trend down, it’s usually a sign of moisture ingress, improper handling, or contamination during refills.

Unplanned Outages Linked to Insulation or Dielectric Problems

If forced outages increase during cold weather, it’s usually a sign that contamination, moisture ingress, or gas decomposition had already been developing before temperatures dropped. Winter simply exposes weaknesses that were not visible during warmer months. Tracking these outages provides valuable feedback on your preventive maintenance program. The goal is not only to restore service quickly, but to understand the root cause so the same failure pattern does not recur in the next cold season.

Response Time During Cold-Weather Alarms or Events

This KPI reflects how efficiently maintenance crews can mobilize under pressure. Faster, more coordinated response times often indicate strong training, familiarity with gas-handling procedures, and clear communication protocols. In winter, delays can cause cascading failures, especially when dielectric strength is already under stress. Improving response time is one of the most cost-effective ways to enhance overall system reliability.

Emergency Gas Purchases vs. Planned Stock

When temperatures drop, logistics constraints increase, and supply lead times can lengthen. Tracking how often emergency SF₆ or alternative gas cylinders are required during winter helps reveal where inventory planning may have fallen short. This KPI drives smarter Q2–Q3 stocking strategies and prevents costly last-minute orders. A well-prepared fleet should enter winter with sufficient high-quality gas on-site, minimizing emergency procurement and improving operational stability.

O&M Cost Per Bay During Winter

Tracking winter-specific operating and maintenance (O&M) costs per bay provides a clear picture of how well your preventative strategies are working. When leak rates are controlled, gas quality remains stable, and crews respond efficiently to cold-weather events, overall seasonal maintenance costs typically decrease. Reviewing this KPI over multiple winters highlights long-term improvements, identifies areas where training or equipment upgrades would reduce recurring expenses, and supports more predictable budgeting.

Pair KPI reviews with weather-risk awareness tools, such as the Winter Storm Severity Index, so maintenance teams can anticipate stress events rather than react to them. Over time, these metrics empower utilities to shift from reactive emergency response to confident, preventive winter asset management.

DILO Solutions That Support Winter Readiness

Preparing a substation for winter requires the right tools, the right gas quality, and teams who know how to work effectively in cold conditions. DILO supports utilities and service contractors with a complete lifecycle approach to insulating gas management, from zero-emission handling to diagnostics, training, and certified gas supply. The goal is to reduce risk, improve reliability, and help teams maintain compliance even during the harshest weather events.

SF₆ & Alternative Gas Service Carts

Not all gas-handling equipment performs the same in freezing temperatures. DILO’s service carts feature moisture-controlled transfer pathways, robust vacuum performance, and reliable filtration systems that maintain gas purity during handling, a crucial requirement when cold temperatures reduce dielectric strength.

For SF₆-installed fleets, explore SF₆ Gas Equipment designed for zero-emission transfer, reclamation, evacuation, and gas refilling. For utilities transitioning to environmental targets or pilot programs involving C4, C5, or other low-GWP insulating gases, DILO also provides Alternative Gas Handling Equipment engineered to manage varying viscosities, condensation, and purity characteristics in cold environments.

This flexibility is especially valuable for mixed fleets, where a single crew may handle multiple gas types during a single maintenance shift.

Continuous Monitoring & Analyzers

Failures linked to moisture or decomposition byproducts rarely happen suddenly—they develop over time. The challenge is detecting changes before winter load and temperature stress expose them. Continuous monitoring systems help utilities shift from reactive troubleshooting to proactive prevention.

DILO’s continuous SF₆ gas-quality monitoring measures moisture, SO₂, and SF₆ purity in real time. Trends can reveal seal fatigue, moisture ingress, or early decomposition—allowing maintenance teams to intervene before failures occur. During winter, this is especially powerful because dielectric margins naturally tighten; having early detection can mean the difference between a planned maintenance window and an unplanned outage.

Certified Gas Supply & Reconditioning

High-quality insulating gas is the foundation of reliable winter performance. Even when equipment is mechanically sound, contamination or insufficient purity can undermine dielectric strength. DILO’s certified gas supply and reconditioning services help utilities maintain consistent gas quality across their fleet, reducing the need for emergency refills during storms when transportation delays and supply shortages are most likely.

Training & Emergency Response Drills

Equipment alone is not enough; teams must be confident and well-prepared. DILO offers training programs tailored to winter operation scenarios, including:

- Safe, zero-emission gas transfer in freezing conditions

- Moisture-control procedures during field handling

- Troubleshooting mixed SF₆ and alternative-gas fleets

- Rapid incident response workflows to reduce outage duration

Training can be scheduled on-site or delivered virtually, enabling teams to sharpen skills before winter peaks.

IGMS: Learn Cold-Weather Gas Handling from Experts (February)

This February, DILO brings industry experts, engineers, utility managers, and field technicians together at the 2026 Insulating Gas Management Seminar (IGMS). The seminar is designed for real-world challenges, not just theory.

You’ll gain:

- Case studies showing how winter equipment failures occurred and how they were prevented in later seasons

- Best practices for SF₆ and alternative gas handling in sub-zero temperatures

- Decision frameworks for planning fleet transition strategies and hybrid-system SOPs

- Hands-on diagnostics training to strengthen gas-quality and leak-detection programs

- Peer networking with other utilities facing the same operational pressures

If your organization is refining winter procedures, training new crews, or preparing for regulatory reviews, IGMS is one of the highest-impact professional development steps you can take.

Proactive Winter Maintenance = Fewer Outages + Compliance + Lower Emissions

Winter can expose weak points in gas-filled assets, but proactive preparation strengthens reliability, improves safety, and protects your utility’s operational continuity. Applying structured inspections, continuous gas-quality monitoring, and strong leak-prevention practices helps teams stay ahead of cold-weather failures.

Now is the time to:

- Register for the 2026 Insulating Gas Management Seminar

- Explore or update your SF₆ Gas Equipment

- Review fleet transition support through Alternative Gas Handling Equipment

With the proper preparation and proactive substation maintenance planning in place, substations remain reliable, operations stay compliant, and maintenance teams are equipped to respond effectively throughout the winter season.