Sulfur hexafluoride (SF6) gas has many uses, primarily in the electrical industry. Utilities use SF6 gas for gas-insulated equipment (GIE) and arc quenching with high-voltage circuit breakers and switchgear. It has multiple other industrial applications, such as in the production of magnesium and semiconductors.

Given its many uses, SF6 is a precious commodity for electrical transmission and distribution. However, it is also a potent greenhouse gas. SF6 emissions due to improper handling techniques or leaks in equipment contribute to climate change. Measuring equipment, such as SF6 analyzers or leak detectors are an essential part of emission-free gas handling. All SF6 service equipment requires careful maintenance.

The Importance of SF6 Measuring Equipment Maintenance

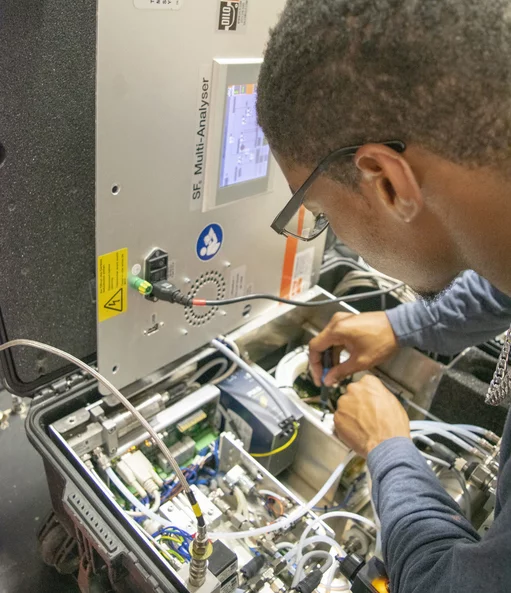

One very important aspect of preventing SF6 emissions during gas handling is to ensure that all equipment used on the job site is in good, working condition. That’s where maintenance comes in! DILO understands the importance of emission-free gas handling. In addition to offering a range of high-quality SF6 gas products, we also offer numerous gas handling services through DILO Direct.

Part of DILO’s mission is to educate SF6 users on how to properly use and maintain their equipment in order to prevent SF6 gas emissions. Maintaining equipment is such an important part of preventing emissions that we’ve decided to dedicate an entire blog series to this topic. Below, in part 2 of this series, we’ll explore why proper maintenance of measuring equipment matters.

Understanding Standard Maintenance for Measuring Equipment

There are several types of SF6 gas equipment, each requiring adequate maintenance to continue working properly. In this blog post, we are focusing on measuring equipment. This category includes analyzers, density monitors, and leak detection equipment. Staying on top of routine maintenance will extend the life of your measuring equipment.

SF6 Analyzer Calibration Intervals

SF6 analyzers are what measure the quality and purity of SF6 gas. They measure the different elements of gas, including:

- CO concentration

- SF6 volume percentage

- H2S concentration

- Moisture concentration

- HF concentration

- SO2 concentration

SF6 gas analyzer calibration is necessary to ensure proper readings. On average, our SF6 analyzers must be inspected every two years. It is important that calibration is performed by a well-qualified technician as improper calibration can cause a range of issues including exposure to arc by-products, faulty readings, and damage to the device. The earlier a device is maintained, the sooner any potential issues will be detected. During inspections, professionals conduct SF6 analyzer calibration and inspect and exchange the following sensors:

SO2 Sensor Exchange

An SO2 sensor detects sulfur dioxide levels for gas measurement. Efficiency is measured as a percentage through a method called “span reserve.” If an SO2 sensor exchange scores below 50%, it could be an indication that it may be time for a replacement. During inspections, professionals will recalibrate the sensor, among other tasks, to ensure the equipment works properly. SO2 sensor exchange should occur at least once every two years.

H2O Sensor Calibration

H2O sensors are designed to detect moisture levels in a supply of SF6 gas. When SF6 gas becomes infiltrated with too much moisture, it can render the gas supply unusable. H2O sensors must be calibrated every two years to remain efficient in detecting moisture.

Volume/Purity (%) Calibration

SF6 gas produced commercially has a minimum purity of 99.9%. A gas purity meter will calculate SF6 purity as a percent (%) of the volume. Leaks, arcing events, and improper gas handling procedures can cause SF6 by-products to form. SF6 by-products are a hazard to human health and SF6 maintenance equipment. Depending on the concentration, toxicity, and reactivity of these impurities, they can significantly affect SF6 and alter its application with insulation and arc extinguishing. To ensure accurate readings, these measuring devices should be calibrated at least once every two years.

Analyzer Compressor Test

Compressors are designed to decrease the volume of gas, which pressurizes it and allows it to run through technology. Compressors are essential to keeping equipment running, making it important to inspect and maintain them regularly. Compressors should be tested every 500 hours of operation. Compressor tests are a routine part of an analyzer calibration.

Storing Measuring Equipment

Another part of efficient maintenance is the proper storing of SF6 measuring equipment. Failure to store equipment properly can decrease its life and cause breakdowns to occur sooner and more frequently. Knowing the correct equipment storing protocols can extend the life of your gas-handling equipment and make the most out of your investment. Below are a few important storage considerations for SF6 measuring equipment:

Store Under Vacuum

Did you know it’s important to not store equipment pressurized with gas? A small amount of gas will be left inside the device and connected hoses after a gas sample is analyzed. It’s necessary to depressurize the gas in an analyzer using the special function “evacuation of device”. Be sure that the analyzer is connected to an external recovery bag or a cylinder to prevent any emissions.

Optimal Temperature

The optimal storage temperature for measuring equipment is -10 to 60ºC, or 14 to 140ºF. The storage temperature is a wide range; However, conditions in the field could cause measuring devices to be exposed to temperatures outside of this range. Therefore, we recommend storing measuring equipment indoors when not in use.

SO2 and H2O

If high H2O levels are detected in a gas sample, it is necessary to dry the device before storage. This is done by selecting “drying of device” under special functions. If high SO2 levels are detected in a gas sample, it is necessary to clean the device by selecting “purging of SO2 sensor” under special functions.

Battery

Battery charge is an important storage consideration. It’s best to avoid a complete draining of the installed battery of any measuring equipment. If stored at 100%, charge the battery after a maximum of 6 months of storage. A minimum charge of 30% is required before storage. Following these simple tips will help preserve the battery life of your device.

DILO’s SF6 Gas-Handling Philosophy

DILO takes a sustainable approach to gas-handling services and equipment. We work with numerous international players in the electrical transmission and distribution industry, including utilities and switchgear manufacturers. Our goal is to help you achieve proper SF6 gas handling and management to prevent SF6 emissions.

We aim to ensure businesses can make the most out of their SF6 gas supply, saving time, money, and resources from replenishing gas. It’s these qualities that make us a leader in the SF6 gas equipment industry.

Do you have questions about measuring device maintenance or gas handling? Please contact us. Our experts are always happy to help!