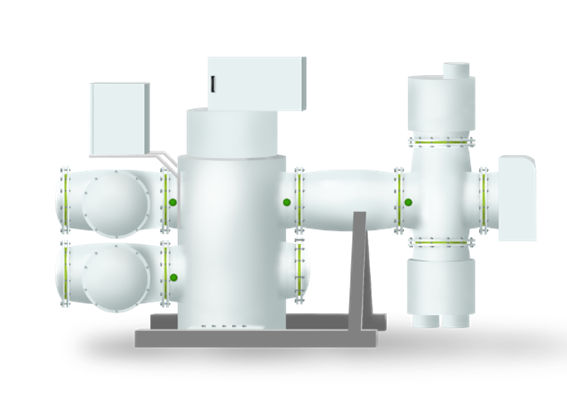

High-voltage switchgear is used to control power flow on the grid and monitor system functionality, which falls into two categories: Air-insulated and gas-insulated. Gas-insulated switchgear is insulated by using a metal capsule filled with gas rather than by using the open air. It is used in city buildings, on rooftops, etc, where there is less space available. The enclosure is typically aluminum, and the gas used is sulfur hexafluoride (SF6). The unit is sealed with O-rings and a grooved and flanged surface to keep the capsule from leaking. The switchgear is held within the enclosure. In some cases, transmission lines may also be gas-insulated.

How Does Gas-Insulated Switchgear Work?

Gas-insulated switchgear works by employing the qualities of SF6 or another dielectric (insulating) gas. Because SF6 is incredibly stable, electricity does not pass well through it, and it can quench the arc formed when an energized circuit breaker is open. Its high dielectric properties allow for a smaller gap between components in the switchgear proper, making it more compact than air-insulated switchgear. It can also handle higher voltages. It is used in medium- and high-voltage applications where space is limited. Components include circuit breakers, disconnectors, transformers, earth switches, and more.

Advantages of Gas Insulated Switchgear

The primary advantage of gas-insulated switchgear is that it takes up much less space. It allows for higher-voltage equipment to be stored in smaller spaces. This is particularly valuable in city centers and more compact industrial estates or in situations where the best place to put electrical gear is the roof.

However, there are several other advantages:

- SF6 dissipates heat more rapidly than air, reducing the risk of equipment overheating and the amount of heat produced by the equipment.

- SF6 captures free electrons effectively, reducing ionization.

- Gas-insulated switchgear is typically more efficient.

- Gas-insulated switchgear is safer because personnel are protected by the earthed metal enclosure and unlikely to come into contact with an arc.

These advantages make gas-insulated switchgear crucial to many power grid and microgrid systems.

Components of Gas Insulated Switchgear

Gas-insulated switchgear comes in a variety of sizes, but a typical gas-insulated substation contains the following components:

- The busbar is typically co-axial in isolated systems. This connects the various components.

- Connectors with spring-loaded plug-in contacts. These connect the different modules.

- Insulation materials, commonly alumina-filled epoxy matrix or stable polymers.

- Disconnectors, in series with the circuit breaker, interrupt small currents and increase safety.

- Grounding switches to ensure that excess current is dealt with.

- Viewports so the switch can be inspected from outside. Many GIS units are hermetically sealed.

- Gas compartments to increase isolation.

- Local control cabinets to control the equipment.

GIS can vary in design, and different units may have different components depending on the exact purpose and the amount of voltage being handled. However, the basic system contains all components within the aluminum capsule. This means that workers are not exposed to the high-voltage components, which complicates access for maintenance or repair.

Applications of Gas Insulated Switchgear

GIS switchgear is used wherever space is limited. This includes heavily built-up areas, but also offshore platforms, industrial plants that have microgrids, and some power plants, especially hydropower. It is used only in medium- to high-voltage applications, which means it is not used in homes or businesses. They are, however, commonly used as part of the power grid in urban areas. Unlike air-insulated substations, which are outside, GIS systems have to be protected from the elements and thus are often inside buildings or structures, although they are also extensively used outdoors with some protection.

They are also commonly used in dry desert and arctic locations, where they can be enclosed in a simple Faraday cage. Another place where GIS switchgear is popular is more expensive neighborhoods, where they can be hidden away and free up space used by larger conventional substations. GIS switchgear in power distribution replaces conventional substations with something that uses less space and requires less maintenance, which can save utility companies money. It's also used in industrial situations to distribute power within a factory or plant without the need for a separate structure for switching.

Comparison: Gas Insulated Switchgear vs. Air Insulated Switchgear

There are a number of key differences between the two. Utilities and others choose depending on the situation, but here are some things to consider:

- SF6 is an extremely potent greenhouse gas, being 22,800 times more efficient at capturing infrared radiation compared to the same amount of carbon dioxide. Many places now have regulatory requirements obliging manufacturers and users of GIS to minimize leaks. It can also produce highly toxic by-products in the presence of moisture.

- GIS takes up a lot less space than air-insulated equipment and can be located inside structures. This makes it ideal for places that require a small footprint, such as offshore platforms.

- GIS requires a lot less maintenance. However, when repairs are needed, they can be incredibly complicated as the gas has to be safely pumped out and stored while the unit is worked on and then pumped back in.

- Because the GIS system is smaller, weighs less, and is an entire unit, it is quicker to install than an AIS system. However, this is reversed if the technician needs to handle the gas.

- GIS systems contain integrated testing instruments.

- GIS systems reduce arc flashes substantially, which improves safety for workers. It also helps with power reliability, as an arc flash in an air-insulated system can sometimes cause a fairly extended blackout.

- GIS systems have a higher upfront cost.

In general, air-insulated systems are better when the substation is outdoors, and there is plenty of space, but it's also worth remembering the maintenance differences. However, the environmental regulation associated with GIS can be costly in time, money, and compliance risk, with more and more jurisdictions placing restrictions on using and handling SF6.

Future Trends in Gas-Insulated Switchgear

The gas-insulated switchgear market is expected to expand, especially in Asia-Pacific and North America. However, there remains a question mark around growing concerns about the use of SF6. Some alternatives are being worked on, like the emerging high-voltage gas-insulated switchgear technologies, clean air GIS, and NCIT. Another possible alternative to SF6 gas is insulating gas mixtures of Fluoronitriles (C4-FN), Carbon dioxide, and Oxygen. , which has a similar dielectric properties but is not as problematic for global warming. In the long term, this indicates a likely deprecation of SF6 in favor of alternatives.

Growing regulation and environmental awareness are likely to reduce the market share of conventional GIS but may not reduce the absolute market size due to development, especially in China and other parts of Asia, and due to their compact size. This might also lead to an increase in the use of hermetically sealed units that are much less likely to leak gas but are also more vulnerable to non-repairable issues leading to premature retirement. The desire to minimize leaks is also leading to measurement and gas monitoring developments, including miniaturized external measurement units that can be used to upgrade existing sealed GIS.

Digitization is also likely to result in the application of IoT technology to GIS, meaning units that will notify a technician when they detect a leak with no need for inspection. This can be integrated into smart grid technology. Many utilities are now constructing digital substations that integrate monitoring and protection with power use measurement.

The grid needs to know when to switch to backup capacity, and GIS has some advantages in this regard. GIS is also useful for on-site microgrids that might combine solar and batteries to provide power to a facility. However, the focus on reducing the use of SF6 is going to lead to alternative gases becoming more popular and likely to an increase in vacuum switchgear, which is starting to be used for high-voltage applications.

Gas-insulated switchgear is a key part of modern power grids and industrial applications. DILO provides equipment to maintain gas-insulated switchgear, including service carts, refilling and evacuating devices, monitoring and measuring devices, etc. We can help with gas handling, keeping your equipment safe and in good condition, and minimizing SF6 leaks. Contact us for more information!

Form Text