AtDILO, we assist companies in optimizing their helium gas consumption and management, reducing reliance on helium suppliers, and ultimately lowering operational costs. Below is all you need to know about a helium recovery system, including future trends in helium recovery.

What is a Helium Recovery System?

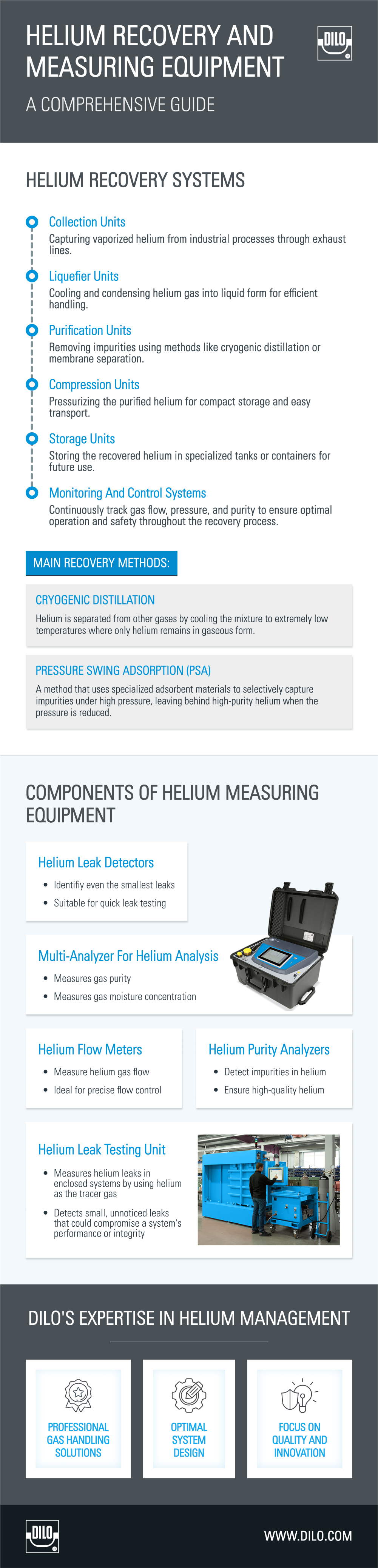

A helium recovery system is designed to manage, recapture, purify, or recycle helium gas from various industrial processes. A comprehensive helium gas recovery solution comprises different components or systems that efficiently manage the entire process. Typically, during the helium recovery process, vaporized helium from various industrial processes is recaptured through exhaust lines.

The exhaust lines then transport the vaporized helium gas to a recovery tank(s), where it is purified to the required standards. The helium gas is finally compressed and transferred to the final storage tank for reuse. Minimizing the amount of helium gas released to the environment not only helps conserve the environment but also reduces costs and guarantees a constant supply of this non-renewable resource.

Types of Helium Recovery Systems

As stated above, the helium recovery system consists of various components, including:

- Collection units: This system consists of pipelines and manifolds that capture helium emitted from various points within the industrial process.

- Liquefier units: This system condenses helium gas to its liquid form mainly to enhance storage efficiency.

- Purification units: These eliminate impurities from the collected helium gas to ensure it meets the desired standards. Some of the methods applied in purification include cryogenic distillation and membrane separation.

- Compression units: The compressor units significantly affect the gas flow throughout the process.

- Storage units include tanks or bags holding or storing the recovered helium gas. Examples of storage solutions include helium collection bags and final holding tanks.

- Monitoring and control systems: These units monitor vital parameters such as gas flow, pressure, or purity and also ensure optimal operation and safety throughout the process.

All these units and components are incorporated into various helium recovery system designs, such as open-loop, closed-loop, or hybrid systems. The main methods used to collect or recapture helium include:

- Cryogenic distillation: Helium remains gaseous even in extremely low temperatures. Cryogenic distillation makes it easier to separate helium from other gases that condense into liquids.

- Pressure Swing Adsorption (PSA). This technology involves multiple vessels, each arranged with adsorbent beds that perform different functions. In the first step, impurities such as nitrogen (N₂) and oxygen (O₂) are removed from the stream, leaving a high-quality helium product. The product is further purified by altering the pressure of the adsorbent bed, which allows for the selective desorption of residual impurities and enhances the purity of the recovered helium.

Components of Helium Measuring Equipment

Helium measuring equipment helps industries achieve greater accuracy, efficiency, and safety and attain their helium recovery goals. The two main measuring equipment include:

Helium Leak Detectors

Helium leak detectors help identify and quantify leaks in a sealed system. Detection systems locate and measure leaks inside or outside a product, utilizing hand-held sniffer type of equipment. The sensors of a leak detector are specifically calibrated for Helium. If Helium is present the levels will be displayed on the device meter.

Multi-Analyzer for Helium Analysis

Multi-analyzer for helium analysis help to provide a quality analysis to determine the purity percentage and contamination levels. Identifying the concentration levels of other gasses or moisture, for example, can help improve processes, systems reliability, and safety standards. .

Helium Flow Meters

These devices help measure the flow of helium gas through pipelines and other circulation systems. They are ideal in applications where precise control of helium flow is vital. Such applications include scientific research, leak testing, or gas distribution systems.

Helium Leak Testing Unit

Helium leak testing unit helps detect or measure helium leaks in enclosed systems by using helium as the tracer gas. Helium's small atomic size and inert nature make it ideal for testing leaks as it quickly passes through the tiniest opening without reacting with other components. Therefore, helium leak detection equipment helps detect small, unnoticed leaks that could compromise a system's performance or integrity. The unit's main fields of application include the automotive industry, refrigeration and HVAC technology, and plant engineering.

Advanced Technologies in Helium Measurement

Advanced technologies in helium measurement focus on enhancing capabilities and performance. For example, advances in microfabrication technology have resulted in developing compact and portable helium detectors ideal for mobile and field applications. The integration of sensor technologies in helium detection has also resulted in enhanced detector sensitivity, stability, and minimized response time. Finally, the latest helium detectors have data logging and real-time monitoring capabilities making it easy to conduct and manage remote operations.

More integration of helium detectors with IoT platforms is expected to occur in the coming years, enhancing connectivity and allowing efficient remote monitoring and real-time data analysis. With more ongoing research on enhancing detection capabilities, helium detectors are poised to become more sensitive, increasing detection limits to identify even lower concentrations of helium.

Applications of Helium Recovery and Measuring Equipment

Helium can be a valuable resource in various industries, which means that an effective method for recovering it plays a key role in conserving these resources. Here are some of helium's most common industrial, scientific, and research applications.

Industrial Applications

The various unique properties of helium make it a valuable resource in various processes across industries. One of the industrial applications that highly utilize helium is welding and cutting. Helium applications are preferred in welding due to their low ignition temperature. The low ignition temperature increases safety, especially when working with hot equipment. Gas-cutting technologies also prefer helium applications due to the element's non-reactive nature.

This inertness prevents unwanted chemical reactions during cutting, resulting in precise and cleaner cuts. Additionally, helium's high thermal conductivity allows even heat distribution through metals and other materials, which enhances the overall productivity and quality of the work.

Another typical industrial application for helium is leak detection. Its ability to diffuse through solids more quickly than air allows it to identify possible leaks effectively. Finally, industries like aerospace and electronics use helium leak detectors in their process to ensure the integrity of their systems.

Scientific and Research Uses (e.g., MRI, Particle Accelerators)

Helium applications are also used in various scientific and research fields, such as MRI and particle accelerators. Typically, MRI scanners rely on superconducting magnets cooled to relatively low temperatures (4K) to capture high-quality pictures of a patient's vital organs, such as the brain. Helium's ability to remain in a liquid state at such low temperatures is utilized to keep these superconducting magnets cool or cold. In particle accelerators, helium is also used to cool the superconducting magnets and other components required for conducting experiments in particle physics.

Economic and Environmental Considerations

According to a report from the U.S. Geological Survey, Mineral Commodity Summaries, thetotal helium production increased by 8% in 2023, indicating the increasing demand for this vital resource. The growing demand highlights the need to create efficient recovery systems and sustainable practices to ensure helium's availability and reduce its environmental impact.

Cost-effectiveness of Helium Recovery Systems

While the initial investment in a helium recovery system may be substantial, adopting one provides long-term savings in a number of ways. By recovering helium, industries minimize the cost of buying new helium gas. This also helps reduce operation costs by shortening costs associated with transporting and storing helium.

Environmental Impact and Sustainability in Helium Usage

Although helium has minimal effects on humans and the environment, its production usually involves energy-intensive processes contributing to greenhouse emissions. Therefore, efficient use and recovery lowers the carbon footprint and the environmental impact of new helium production. Also, a helium recovery system reduces the need to extract more helium, which helps conserve and extend the lifespan of available resources.

Future Trends in Helium Recovery

Looking ahead, the anticipated trends in helium recovery include:

- Innovations in helium extraction and recovery technologies: New approaches and innovative processes for helium recovery, such as advanced membrane technologies and improvements in the cryogenic distillation process, will ensure more efficient and sustainable recovery systems.

- Market trends and demand outlook: The sustained growth in industries relying on helium applications demands the development of more efficient helium recovery solutions. We are witnessing continued progress in fields like electronics, more space exploration, and continued innovation in fields like electronics. All these industries highly utilize helium, driving the demand for advanced recovery technologies.

- Stringent helium production and usage policies: Given the scarcity of helium and the environmental impacts during its production and usage, the government and numerous regulatory bodies are more likely to impose strict regulations on helium usage and waste. This will encourage numerous industries to adopt helium recovery systems to comply with environmental standards.

Optimize Your Helium Management Today with DILO

When managing helium gas, working with a reputable gas handler is essential to ensure high-purity helium supply, optimal system design, compliance with safety standards, and cost efficiency. At DILO, we offer professional gas management solutions with a focus on quality, innovation, and customer satisfaction. Our five decades of experience and commitment to safety and efficiency make us the industry's #1 reputable and trusted gas handling specialist.

We provide numerous helium management solutions, including leak detection and helium analysis. Contact us today to learn how we can support your gas handling needs.