Sulfur hexafluoride (SF6) is frequently used in electric power systems and other industries. While it’s non-toxic and thermally stable, SF6 is also the most potent greenhouse gas. That’s why it’s so important to strive for zero emissions when working with SF6: if this gas escapes into the environment, it can remain in the atmosphere for over 3,000 years. Don’t be a gashole – use these SF6 gas handling pro tips to keep your team safe and minimize the risk of emissions.

Best Practices for SF6 Handling

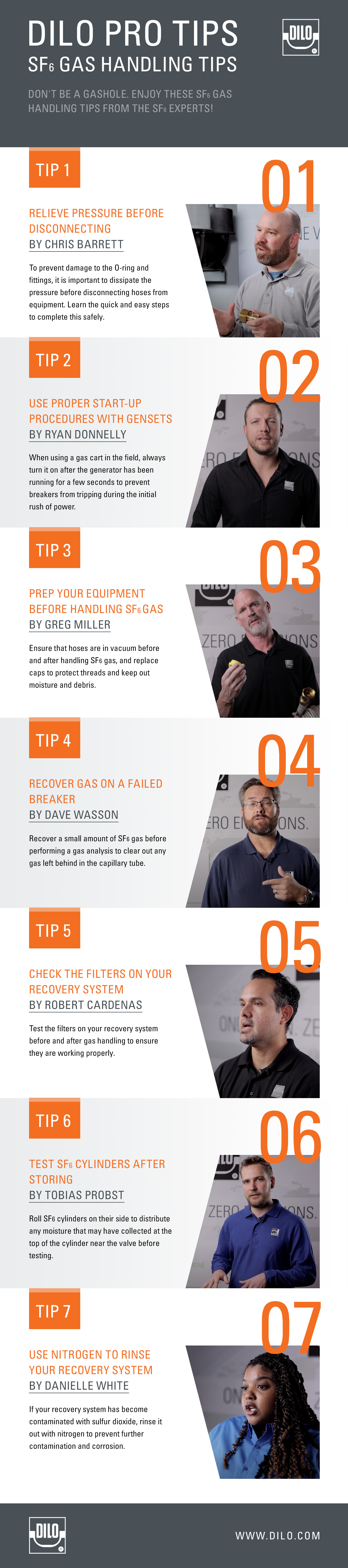

At DILO, our team has extensive experience working with gas-insulated equipment (GIE). To support our customers, we’ve compiled these pro tips:

Relieve Pressure Before Disconnecting

When you’re dealing with high-pressure connections, it can be difficult to disconnect a hose from a fitting. DILO’s fittings use a unique tongue and groove seal, but they also have a temporary O-ring that traps a small amount of pressure. Dissipating that pressure ensures the O-ring won’t get damaged or lost.

The female fitting will have a little built-in play, and it will take about six complete turns to separate the male and female fittings. Once you can see two or three threads on the male part, you should be able to wiggle the fittings so that the gas dissipates while preserving the O-ring.

Use Proper Start-Up Procedures

When you’re using a gas cart in the field, you’re probably running it off of a portable generator. One basic but critical tip is to always leave the gas cart powered off until the generator has been up and running for a few seconds.

When the generator first turns on, it creates a sudden rush of power. If the connected gas cart is also powered on, the initial high voltage could potentially damage the equipment. Always use this start-up procedure:

- With the gas cart power switch in the “off” position, start up the generator.

- Once the generator has reached idle speed after five to 10 seconds, flip the gas cart power switch to the “on” position.

When a job is complete, simply perform these steps in reverse: switch the gas cart power switch to the “off” position, then turn off the generator.

Prep Your Equipment Before Handling SF6 Gas

Ensure that your hoses are always in vacuum before and after SF6 gas handling, and always replace caps to protect the threads and keep out moisture and debris. Proper hose and cart care before and after each job will reduce your prep time in the future.

Recover Gas on a Failed Breaker

If you have a breaker that you suspect or know has failed, you’ll want to perform a gas analysis. Before doing so, it’s best to recover a small amount of SF6 gas beforehand. Gas can be left behind in the capillary tube – once you’ve cleared that out, you’ll get a more accurate result on your analysis. *remember to use an inline prefilter when recovering, to protect the recovery equipment from gas by-products.

Check the Filters on Your Recovery System

It’s important to test the filters on your recovery system if you think they may need to be replaced. To check if the filters are exhausted, you’ll want to test before and after gas handling. Your pre-test will help determine gas levels before handling, as well as contaminant levels. Record the information, then run the gas through the recovery system.. Your test results should always be better than the pre-test numbers. If results have improved, you know your filters are working. If test results are the same or worse, you know the filters have been exhausted and should be exchanged.

Test SF6 Cylinders After Storing

If you’re using an SF6 cylinder that has been in storage, there’s always a risk that moisture has collected in a pocket at the top of the cylinder near the valve. This could lead to an inaccurate analyzer reading that doesn’t reflect the actual moisture content inside the cylinder. To fix this, lay the cylinder on its side and gently roll it back and forth. This evenly distributes moisture throughout the cylinder so you can get an accurate reading.

Use Nitrogen to Rinse Your Recovery System

If you suspect your recovery system has become contaminated with sulfur dioxide (SO2), you can use nitrogen to rinse out the internal components. This helps prevent further contamination and corrosion. Remember to remove any SF6 from the system before you introduce nitrogen. Keep in mind that you may need to regulate the pressure on the nitrogen bottle before running the nitrogen through the system. Afterward, you’ll need to evacuate the cart to remove any nitrogen in the system.

Always wear proper PPE, as byproducts of SF6 can be hazardous to humans. All items requiring disposal after cleanup, such as exhausted filter cartridges, should be neutralized in compliance with safety standards. And be sure to verify SF6 quality before and after gas recovery to minimize the risk of harmful byproducts. Additional information is available in DILO Academy’s Emergent By-Product Cleanup Services webinar.

Note that DILO customers can always request onsite support from our service group, DILO Direct to perform system maintenance services.

Need More SF6 Handling Pro Tips?

There’s no substitute for knowing how to properly operate SF6 gas handling equipment. That’s why it’s so important to have well-trained technicians on your team as the first line of defense against SF6 emissions. For in-person and virtual training sessions on gas handling, be sure to check out DILO Academy. We are proud to be accredited by International Accreditors for Continuing Education and Training (IACET) and offer IACET Continuing Education Credits (CEUs).

Don’t forget to save the date for our upcoming Insulating Gas Management Seminar. Taking place February 7-8 in Clearwater Beach, Florida, this seminar will feature presentations from industry experts, interactive breakout sessions, and opportunities for networking and socializing. For more information on continuing education and SF6 gas handling pro tips, contact us today.