Although sulfur hexafluoride (SF6) is a highly stable gas in a sterile environment, it is susceptible to contamination in normal working situations. Learn more about SF6 by-products and best practices for performing an SF6 gas quality check.

SF6 Properties

Sulfur hexafluoride (SF6)is:

- Non-toxic

- Non-flammable

- Odorless

- Colorless

- Chemically stable

These properties make SF6 gas a good insulator in electrical systems. Utility companies use SF6 gas in circuit breakers, transformers, and switchgear because of its unmatched dielectric strength and arc-quenching capabilities.

SF6 Contaminants

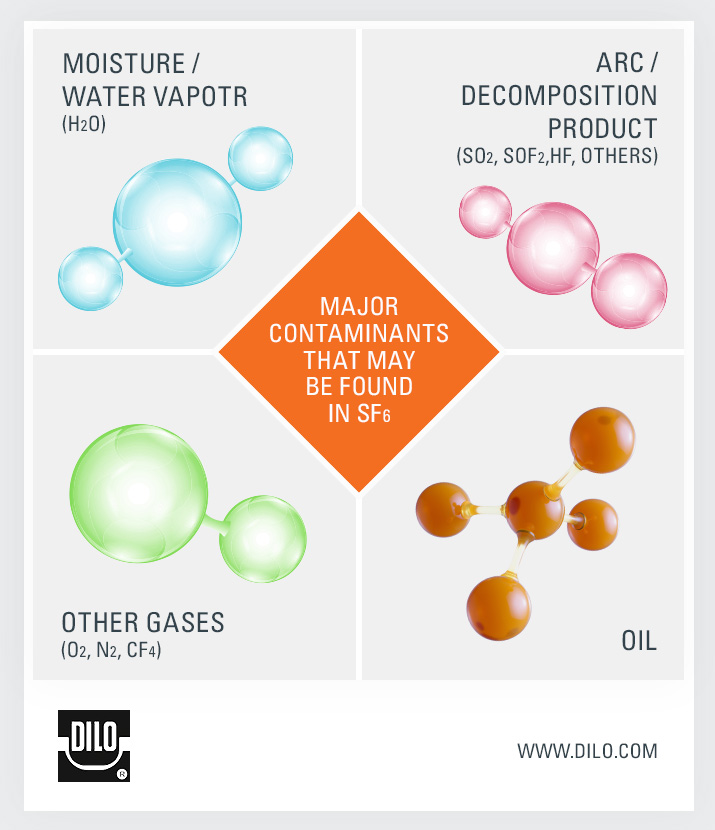

Major contaminants that may be found in SF6 gas include:

- Moisture from water vapor

- Oil

- Decomposition products, such as sulfur dioxide (SO2), hydrogen fluoride (HF), and thionyl sulfide (SOF2)

- Other gases, like oxygen, nitrogen, and carbon tetrafluoride (CF4)

- Particulates

- Dust particles

Contamination can happen for a variety of reasons. Gas-insulated equipment (GIE) may leak, or technicians may make mistakes during gas handling. Pre-mixtures that contain gases other than SF6 can also lead to cross-contamination.

Moisture as a Contaminant

Moisture might not seem as harmful to SF6 as debris or other gases, but it can be a major issue. Leakages, natural “off-gassing” of material, and handling errors can cause moisture to get into a gas compartment. Unfortunately, high concentrations of moisture reduce the insulating properties of SF6, creating unsafe conditions. If SF6 gas breaks down, due to high heat, to individual Sulfur and Fluorine, the (S) and (F) can attach to moisture (H20), forming toxic and corrosive decomposition products.

SF6 By-Products as Contaminants

If the SF6 molecule does break down, it can decompose. Moisture, air, and heat can act as reaction partners. For example, under partial discharge, SF6 will decompose into

- Disulfur decafluoride (SF5)

- Sulfur tetrafluoride (SF4)

- Sulfur difluoride (SF2)

This decomposition can damage GIE, reducing operational safety and creating health hazards. Exposure can lead to:

- Eye, nose, and throat irritation or burns

- Lung damage

- Bronchitis

- Rashes

- Nasal congestion

Technicians should always perform SF6 gas handling in a controlled environment with the proper personal protective equipment (PPE). Seek medical attention immediately in the event of exposure.

Other Gases as Contaminants

Oxygen (O2) and nitrogen (N2) can also contaminate SF6 gas. Leaky hoses, improper handling, or poorly maintained handling industrial gas equipment can lead to N2 and O2 mixing with the SF6 in the gas compartment. Oxygen and Nitrogen mixed with SF6 delutes the SF6 and lowers its dielectric strength , weakening its insulating properties. At high concentrations, other gases mixed with SF6 can reduce the insulating properties of SF6 gas, creating a dangerous situation for technicians.

Oil Mist as a Contaminant

Typically, SF6 gas becomes contaminated with oil mist if technicians do not use oil-free handling devices. Even small amounts of oil can carbonize, reducing the equipment’s insulating capacity. Operators should be careful to always use oil-free compressors and pumps.

SF6 Gas Analysis

Performing an SF6 gas quality check before any type of gas handling is imperative.

Your SF6 gas analysis must include:

- Moisture measured in parts per million volume (ppmv)

- Decomposition content measured in ppmv

- A purity test measured as a percentage of the total volume

The maximum contaminant levels for SF6 for in-service equipment were established by International Council on Large Electric Systems (CIGRE) in 1997. They are:

- Non-reactive gases: up to 3%

- Arc by-products: 500 ppmv

- Moisture: 200 ppmv

However, DILO recommends 0 ppmv for any SF6 by-products. If technicians do not have access to field-level devices, gas samples can be sent to a lab for analysis. But using a lab can be costly and time-consuming, so for immediate results, it is best to have a gas analyzer onsite.

SF6 Gas Analyzers

Gas analyzers are measuring devices that safely extract SF6 from GIE, assess its properties, and check for impurities. At DILO, we sell several different kinds of SF6 gas analyzers:

SF6 Multi-Analyzer

This is a lightweight analyzer with a touchscreen interface. The SF6 Multi-Analyzer can measure up to six parameters with a single sample, including:

- SF6 volume percentage

- Moisture concentration

- SO2 concentration

- HF concentration

- H2S concentration

- CO concentration

SF6 Mirror Analyzer

This portable field analyzer has data storage for up to 500 tests and has replaceable sensors for rapid testing. The SF6 Mirror Analyzer measures:

- SF6 volume percentage

- Moisture concentration

- SO2 concentration

SF6 Gas Monitoring System

This type of analyzer is used for continuous monitoring. The SF6 Gas Monitoring System tracks the same parameters as the SF6 Multi-Analyzer .

Arc By-Products Measuring Device

This rechargeable analyzer can check for decomposition products like SO2 and SOF2. The Arc By-Products Measuring Device responds in less than 15 seconds and is emission-free.

What to Do if You Find Contaminants

When it comes to responsible gas handling, remember the three Rs:

- Reuse

- Recover

- Recycle

An SF6 gas analyzer can check potentially contaminated gas. If contaminants are identified, you may be able to remove them onsite and safely recycle the gas. Solid decomposition products can be removed with a particle filter or a dry vacuum cleaner. Gaseous decomposition products can be removed via pre-filter connected between the gas compartment and the service cart.

The exception to this rule is contaminants like air, N2, and CF4. These must be removed in a controlled cryogenic environment. An experienced service provider like DILO can recondition the gas offsite.

At DILO, we’re committed to helping utility companies and private corporations ensure emission-free SF6 gas handling. As a leading SF6 gas specialist, we offer IACET-accredited continuing education in safety and proper handling. For more information about upcoming training opportunities, contact us today.