The Importance of SF6 Leak Detection in Preventing Emissions

SF6 is commonly used as a dielectric among various industries given its high thermal conductivity and stable molecular structure. SF6 has unmatched arc-quenching ability, but unfortunately is also potent greenhouse gas that contributes to climate change. If you’re interested in learning more, we have covered more extensively in our past blog post on SF6 Emissions and What Can Be Done to Reduce Them.

To help minimize any potential emissions into the atmosphere, SF6 leaks must be swiftly and properly identified. Knowing where to look for SF6 leaks as well as what equipment to use to detect them is the best way to ensure this. It is important to realize that SF6 leaks can occur at any point in gas handling, whether that is while SF6 gas is in storage in cylinders or acting as an arch-quenching insulating medium in Gas Insulated Equipment.

Common Leak Points

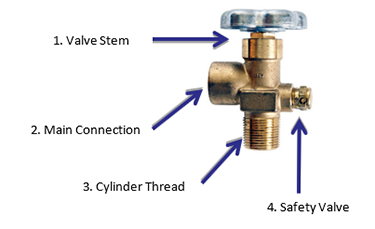

Though SF6 leaks can occur at any point during the gas handling process, today we will focus on checking for leaks on cylinders and look at common leak points in a cylinder. SF6 leaks can occur in several areas on the valve area of the cylinder, such as the main valve, the safety valve, or the cylinder valve itself. It is important to test each of these areas when checking for a SF6 leak. Figure 1 below displays the most common leak points that occur within a valve.

General Leak Inspection Points for Cylinders

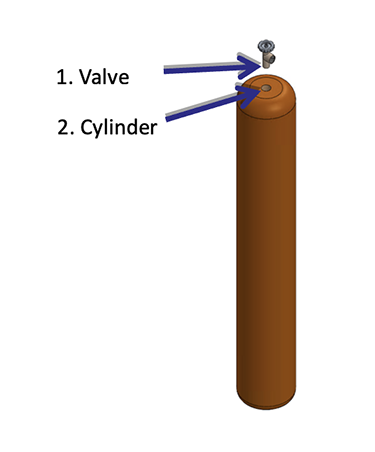

Among cylinders, leaks typically occur within the top portion of the container and it is recommended to inspect these areas regularly. The most Common leak points in the SF6 cylinders are listed below in Figure 2.

Which Leak Detectors Are Best Suited to Which Applications?

There are several SF6 leak detection methods to choose from and the ideal method will depend on your application and budget. Other outside factors such as temperature, equipment reliability and even breaker pressure can also potentially affect leak detection. Below, we touch on each common type of leak detection methods and their advantages and disadvantages.

The Snoop Solution

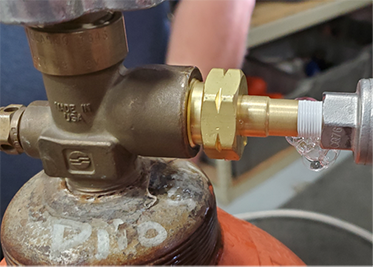

The Snoop Solution is composed of deionized water and a surfactant that produces sustained bubbling when it comes into contact with gas leaks. You can also make your own “soapy solution” by creating a mixture of 20:1 water and soap and then adding the mixture into a spray bottle. This solution can be sprayed directly onto areas where leaks are suspected, such as flanges or valves to identify the source. The Snoop Solution is non-toxic, non-corrosive, non-flammable and does not contain chlorine. This formula also contains a corrosion inhibitor for added protection.

One advantage of utilizing the Snoop Solution for leak detection is that it is an easy, relatively inexpensive option for discovering leak sources. This solution might also be a great option for detecting leaks in some hard-to-reach areas. Possible disadvantages of the Snoop Solution include potential skin irritation with use as well as weather conditions potentially limiting use. Another drawback with this solution is that it is a less advanced, less accurate option than other detectors on the market.

Handheld Leak Pointer

Handheld leak detectors, like DILO’s 3-033-R002, are great for quick tracing of small SF6 leaks. This is a small and lightweight device that is also cordless. The SF6 Leak Pointer can detect SF6 leaks in different sensitivity levels with a response rate of just one second. The SF6 Leak Pointer is easy to operate with one hand and leakage data is clearly presented on an LED display. In addition, an audible alarm alerts the user to the presence of SF6 leaks. The SF6 Leak Pointer clears itself quickly, even after detecting large SF6 leaks.

The Handheld Leak Pointer’s sensitivity level is 5 g SF6 / year (5 grams of water mass as an example per year are equal to = 0.00000016 mL/sec). One weakness of the Handheld Leak Pointer is that it is susceptible to false-positive readings due to quick movements, windy conditions, and dirty sensing tips. The Handheld Leak Pointer is great for detecting small leaks fast. Compared to the Snoop Solution, this device has higher sensitivity to detect small SF6 leaks by utilizing the high voltage ionization measuring principle as well as presenting leakage data on an LED screen. It should also be noted that the Snoop Solution should be used only after a “sniffer type” of leak detection. When you are using a sniffer type of device, the device mustn’t draw in moisture from the snoop or soapy water solution. This can lead to false-positive readings or potentially damage the leak detector

Portable SF6 Gas Monitor and Leak Detector / Part Number: 3-033-R502

The Portable SF6 Gas Monitor and Leak Detector is an advanced personal gas monitor that uses long-life, non-dispersive infrared sensor (NDIR) technology for analyzing and checking low-level gas concentrations in the ambient environment. With very fast response and clearing times, this unit can identify and pinpoint very small levels of sulfur hexafluoride gas in ambient air, showing real-time concentrations in either parts per million (ppm) or elapsed time weighted average (TWA) with a resolution down to 1 ppm.

Although this device is not intended to be used as a solo device for confined space entry, it will complement existing gas monitoring safety equipment. In addition to its monitoring capabilities, the Portable SF6 Gas Monitor and Leak Detector can also serve as a portable leak detector. In this pro-tip video, DILO’s General Manager, Billy Lao, explains how this unit can double as a room monitor to detect SF6 gas leaks.

SF6 Gas Room Monitor

The SF6 Gas Room Monitor is a monitoring system that can be used for continuous leak detection in up to 16 separate test zones and the longest sampling distance in the industry at 1,200 feet. This device also has the ability to retain a record of former analyses that can be easily accessed for examination. If a gas leak is detected within one of the zones, the SF6 Gas Room Monitor is equipped with audible and visual front panel displays and offers four relay contacts that can be preset to activate external alarms. This device encourages safety and helps to prevent potential emissions through its continuous monitoring and minor periodic maintenance (i.e. the occasional replacement of filters and active diagnostics that continuously check the system for proper operation).

Though the SF6 Gas Room Monitor is great option for continuous leak detection and monitoring, one drawback is that this device cannot pinpoint exact leak locations, but rather will merely alert that a leak has been detected.

Proper Training in Leak Detection

Above, we have highlighted the various leak detection equipment that may help to detect SF6 leaks. Though these breakdowns are helpful, the team here at DILO still strongly advocates for the importance of receiving proper training in these areas and encourages anyone handling SF6 gas to gain this crucial knowledge. Properly trained technicians are the first line of defense against SF6 leaks. Check out our available trainings here – we are now also offering an accredited self-paced virtual course that you can take at your own speed!

To contact our team at DILO directly, click below!

Contact Us