In the world of electrical transmission and distribution, responsible handling of sulfur hexafluoride (SF6) gas is crucial. SF6 is widely used due to its excellent insulating properties, but it is also a potent greenhouse gas. Organizations must ensure efficient SF6recovery, recycling, and reuse to minimize emissions and comply with industry regulations.

Understanding Proper SF6 Handling

DILO follows the S.E.A.L. motto when it comes to gas handling:

- Safety: Minimizing risks in SF6 handling.

- Environmental Responsibility: Reducing emissions to protect the planet.

- Accounting: Ensuring accurate tracking of SF6 gas usage.

- Legal Compliance: Meeting industry regulations and standards.

Reducing emissions is both a corporate and personal responsibility. By understanding the best practices and selecting the right equipment, organizations can improve efficiency, reduce costs, and stay compliant with regulatory standards.

The Root Causes of SF6 Emissions

Several factors contribute to SF6 emissions, including:

- Improper handling practices during gas filling, maintenance, and recovery.

- Nameplate inaccuracies on Gas-Insulated Equipment (GIE), leading to miscalculations of gas volume.

- Gas leaks in high-voltage equipment due to aging components or manufacturing defects.

- Inefficient recovery systems that fail to capture the maximum amount of gas during servicingservice.

SF6 emissions are subject to strict regulations. For example, IEC standard 62271-203 specifies leak rate limits:

- High-voltage equipment: Maximum leak rate of 0.5% per year.

- Medium-voltage equipment: Maximum leak rate of 0.1% per year.

The Three R’s of SF6 Gas Handling

To ensure responsible and efficient gas management, organizations should follow the Three R’s:

- Recovery: Removing SF6 from GIE and safely storing it. Remember, the perfect recovery is achieved with zero emissions!

- Recycle: Filtering out contaminants like moisture, decomposition byproducts, and oil to restore gas purity.

- Reuse: Processing recovered gas for reinjection into equipment or the supply chain, avoiding the need for new SF6 purchases.

By following these three principles, businesses can extend the lifecycle of SF6 gas while reducing environmental impact and operational costs.

Determining Gas Volume and Residual Gas

Understanding SF6 gas volume calculations is essential for accurate recovery and compliance:

- SF6 volume is calculated based on pressure and temperature conditions.

- Proper recovery requires reducing residual pressure in the GIE to ensure that all SF6 is captured.

- Using mass flow meters helps quantify the amount of gas recovered and minimize losses.

- Older recovery systems may leave behind significant residual gas, contributing to avoidable emissions.

Modern Recovery System Standards

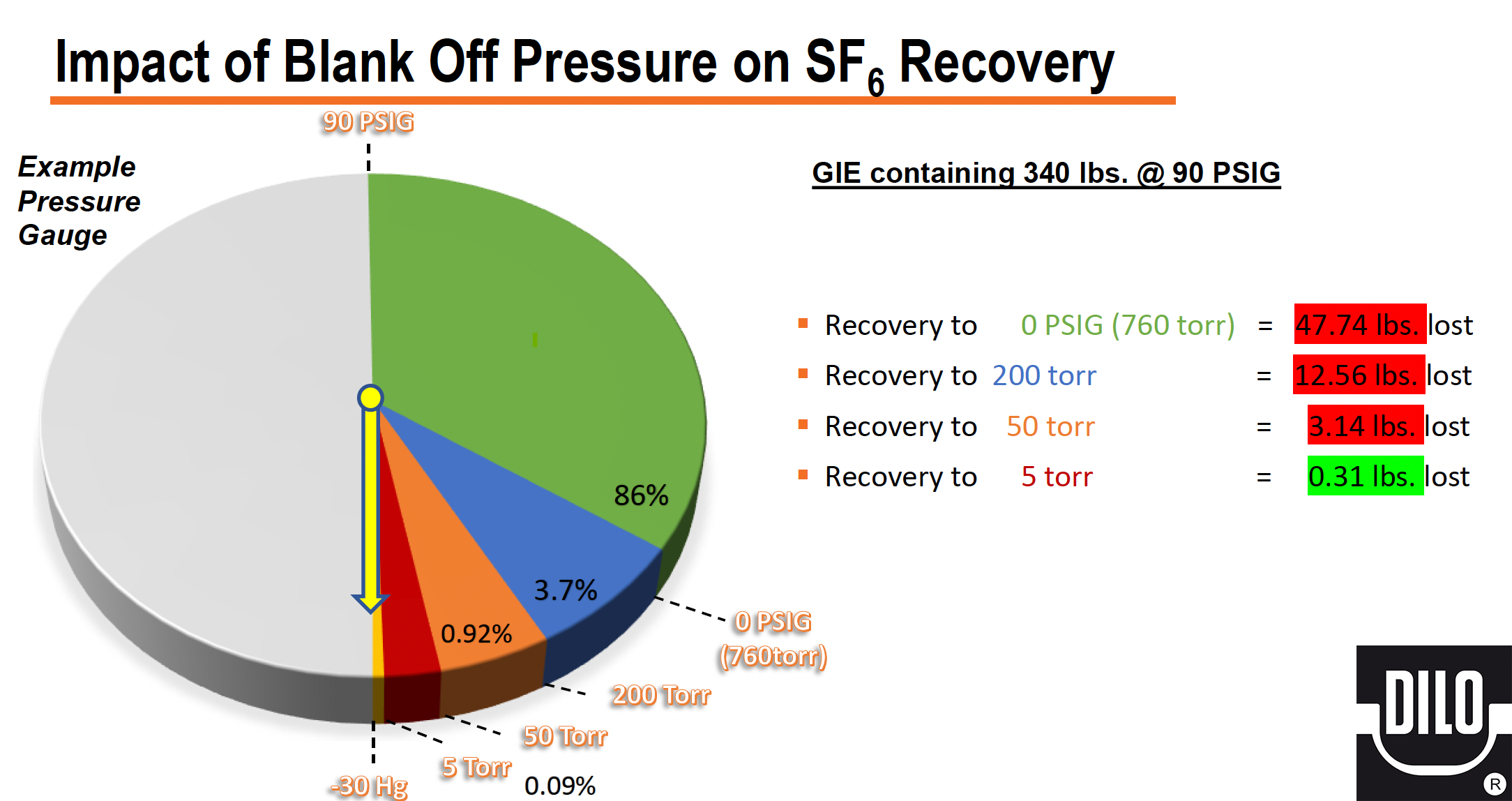

Older recovery systems often left behind significant residual SF6, leading to emissions and waste. Today’s advanced systems can achieve near-total gas recovery by reducing blank-off pressure to ultra-low levels:

- For <100 lbs. of SF6: Recovery to < 5 mbar (3.75 torr) is recommended.

- For >100 lbs. of SF6: Recovery to < 1 mbar (0.75 torr) is optimal.

At these levels, nearly 100% of the gas is recovered, reducing emissions and minimizing environmental impact.

Key Factors in Selecting an SF6 Recovery System

When choosing an SF6 recovery system, consider the following factors:

- Required recovery time

- Final vacuum level to be achieved

- Volume of the largest gas compartment

- Maximum permissible storage weight

- Cycle time for SF6 recovery, filling, and air evacuation

- Regulatory compliance requirements

- Budget constraints

- Efficiency of the system in minimizing gas loss

The Importance of Proper Equipment Sizing

Using an undersized recovery system can significantly increase recovery time. For example:

- A GIE containing 150 lbs. of SF6 at 75 PSIG using a small recovery system may take 15+ hours to reach proper recovery levels.

- An adequate recovery system can reduce this time to 3 hours.

Additionally, hose length impacts recovery efficiency:

- A 15’ hose allows recovery to <1 torr in 3 hours.

- A 65’ hose may double the recovery time to 4.5+ 6+ hours.

DILO’s Industry-Leading Recovery Solutions

DILO provides cutting-edge SF6 recovery compressor systems tailored to different needs:

- Small systems: Recovery rate of 1.9 m³/h

- Medium systems: Recovery rate of 6.5 m³/h

- Large systems: Recovery rate of 40 m³/h

- Extra-large systems: Enhanced capacity with vacuum potential

Our advanced technology ensures faster recovery times, near-total gas capture, and compliance with environmental regulations. We even have an APP to help you find the right recovery system to suit your needs. Additionally, DILO offers training programs and maintenance services to help organizations optimize SF6 gas handling.

The Cost of Not Upgrading Your Recovery System

Failure to upgrade to a modern SF6 recovery system can result in:

- Higher operational costs due to inefficient recovery processes.

- Increased regulatory risks due to SF6 emissions violations.

- Environmental consequences resulting from excess gas leakage.

- Lower equipment lifespan as contaminated gas affects performance.

By investing in DILO’s recovery systems, organizations ensure long-term cost savings, regulatory compliance, and environmental responsibility.

Optimize Your SF6 Gas Handling with DILO

For over 50 years, DILO has been a trusted partner in SF6 gas handling. Our innovative recovery solutions help businesses reduce emissions, improve efficiency, and comply with industry standards.

If you're looking for the right SF6 recovery system, contact DILO today. Our team can help you select the best system to optimize your operations and protect the environment.

Don’t let inefficient gas handling slow you down—upgrade your SF6 recovery system today!

Contact Us