SF6 cylinder blanket heaters are a simple, cost-effective way to remove the maximum amount of SF6 gas from a cylinder during gas handling, thereby avoiding emissions. Cylinders filled with SF6 gas often contain both liquid and vapor forms of the gas. The colder a cylinder is, the more liquid form of the gas it will contain.

How do SF6 Gas Tank Heater Blankets Influence Emission Rates?

When sulfur hexafluoride is being removed from the cylinder, the liquid portion of SF6 will vaporize and cool in the process. The cooling can get to a point where the liquid portion of SF6 will no longer convert to gas.

Liquid SF6 in a cylinder is a problem during gas handling because only the gaseous form of SF6 can be removed from a cylinder. Liquid SF6 will be left at the bottom of the cylinder leading to potential emissions and the loss of SF6 gas from your company’s stockpile.

SF6 gas cylinder blankets are the perfect way to combat this issue and ensure all gas is removed from the cylinder during evacuation. Heater blankets are simply strapped to the lower part of the cylinder to prevent liquefaction of SF6 gas. An integrated thermostat prevents the gas bottle from being overheated.

DILO Pro-Tip: How to Properly Use Heater Blanket on SF6 Gas Cylinder

Best practices and tips for using gas cylinder heater blankets for SF6 gas handling:

- Ensure the cylinder valve is closed before using the heater blanket.

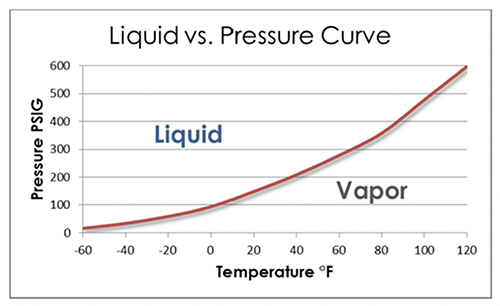

- For best results, heat cylinders until the gas is 120oF. A pressure gauge used along with Liquid vs Pressure Chart above will help determine the temperature of SF6 gas.

- It’s best to preheat cylinders prior to beginning service to allow time for the cylinders to warm up. Thermostatically controlled heater blankets allow for safe overnight heating.

- Use up to three heater blankets per cylinder for faster results.

- Keep cylinders in a temperature-controlled environment to minimize temperature fluctuations.